Summary of battery standards and regulatory knowledge from around the world

Time:2023-09-03

Views:722

Unfortunately, in the past two decades, lithium batteries have made headlines several times in terms of safety. Many incidents caused by lithium batteries have caused billions of dollars in brand and property damage. Some accidents have also caused personal injury or death.

Due to the unstable nature of lithium-ion batteries, many organizations/countries have established regulations to ensure that they receive safe batteries. This article will study which battery regulations may need to be complied with by batteries around the world, and what content they need to include.

Unfortunately, in the past two decades, lithium batteries have made headlines several times in terms of safety. Many incidents caused by lithium batteries have caused billions of dollars in brand and property damage. Some accidents have also caused personal injury or death. Some of the most sensational events include:

• United Parcel Service (UPS) freight flight 6 crashed in 2010, resulting in the deaths of two pilots; The root cause is the lithium ion batteries shipped in the cargo hold.

•In 2006, Sony batteries, mainly used for Dell laptops, began to catch fire; The root cause is the short circuit caused by poor impurities in the battery cells (over 9 million batteries have been recalled).

• In 2013, Boeing‘s Dreamliners were grounded due to battery fires; The root cause is an internal short circuit in the battery cell (causing over $600 million in losses to Boeing).

•The Samsung Note 7 battery started to catch fire in 2016; The main culprit of multiple incidents was the manufacturing problem of the battery cells, which caused multiple injuries. Due to the recall, Samsung lost over $5 billion.

Figure 1: UPS Flight 6 crashed due to lithium-ion battery failure (Image provided by The Aviation Herald)

These examples only emphasize some events related to lithium-ion batteries and their potential harm. Due to its unstable nature, many organizations/countries have established regulations to ensure that they receive safe batteries. This article will study which battery regulations may need to be complied with by batteries around the world and what content they need to include.

What regulations do you need?

To determine which regulations your rechargeable lithium-ion battery solution may need to meet, you need to ask yourself some questions. Do these batteries themselves need to be transported? 99% of the time, the answer is yes. If so, then you will need to undergo UN 38.3 testing (see Transportation Regulations section). Next, do you want to ship the battery products to Europe (EU)? If so, then you will need to undergo IEC 62133 testing (see international regulations). Will your battery be used in devices that comply with UL terminal device specifications (requiring the battery to also pass UL certification)? If so, then you will need to undergo UL2054 testing (see US safety regulations). Are your batteries being shipped to China, Russia, Thailand, India, South Korea, and Japan? If so, additional testing is required, and each country has its own specific requirements (see other regulations).

Transportation regulations

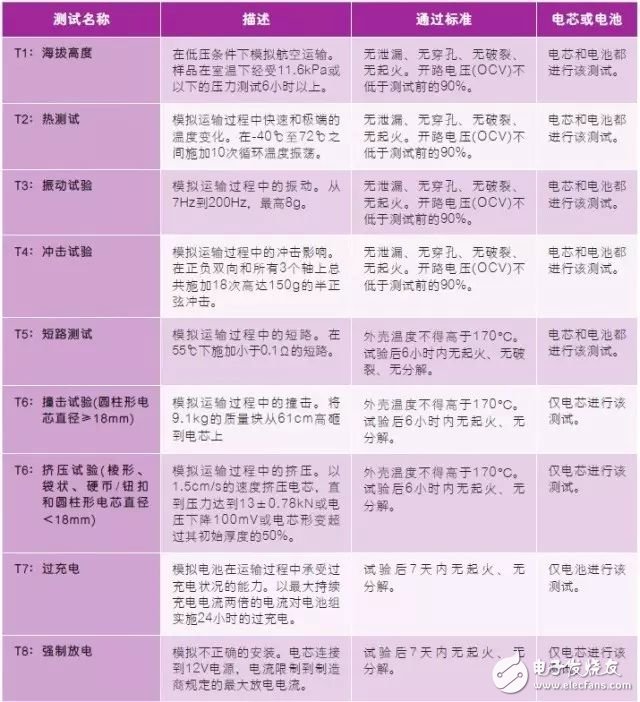

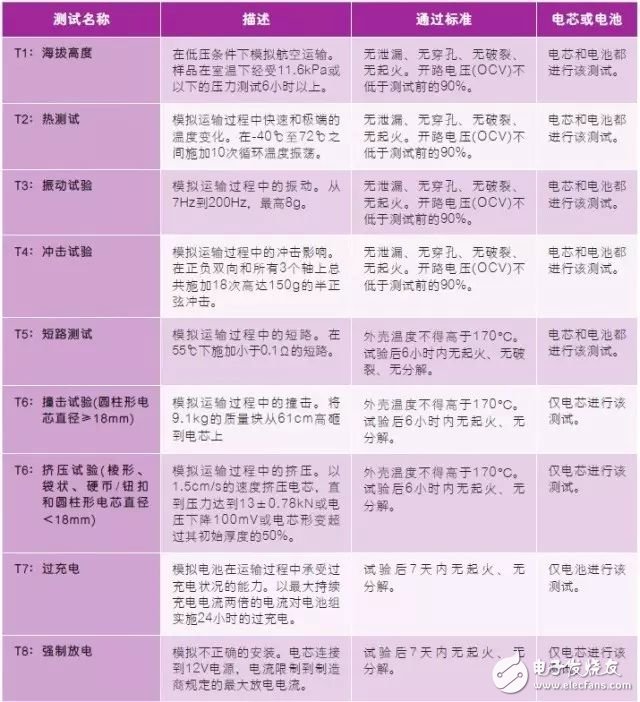

The United Nations has classified lithium-ion batteries as dangerous goods and has proposed suggestions on how to transport them. Section 38.3 of the United Nations Manual Transport of Dangerous Goods provides detailed information on which lithium-ion batteries meet the conditions and how to conduct testing to ensure transportation safety. The United States Department of Transportation (DOT), International Civil Aviation Organization (ICAO), and International Air Transport Association (IATA) have mandated testing of batteries in accordance with Section 38.3. Table 1 lists the tests that batteries and/or cells need to undergo before being transported for acceptance.

Table 1, Complete List of UN 38.3 Tests

This test can be self certified, but a test report with detailed test result data needs to be generated.

US safety regulations

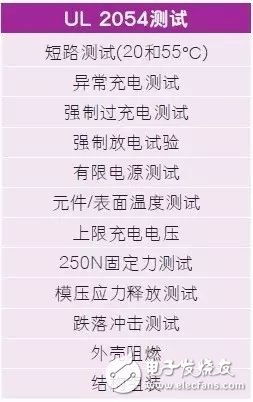

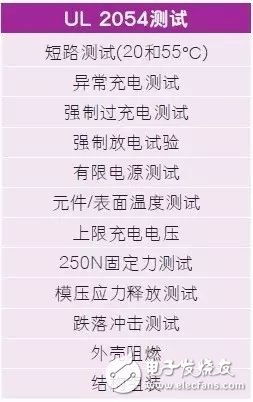

In the United States, there are two main battery standards related to batteries and small portable batteries: UL1642 and UL2054. UL1642 responds to a single battery cell, while UL2054 is suitable for small rechargeable battery packs. UL2054 requires batteries to pass UL1642 certification. Although UL2054 is not a mandatory test for products shipped to the United States, American terminal equipment standards typically have this requirement, and this is a very rigorous test as it requires a fault to be applied to the battery pack. The fault is applied to a non UL rated component. This requires redundant protection in the design to pass several UL2054 tests.

The UL2054 standard includes electrical and mechanical components and requires structural assembly inspections to ensure that the battery is manufactured according to the standard, such as the type of plastic used, wall thickness, and quantity of non UL qualified materials used. Table 2 lists the UL2054 tests.

Table 2, UL2054 testing

There are two options for UL testing: listed and recognized. Listing ensures that the product has passed all tests as required and has been produced according to specifications. Approval means that the battery pack installed in the factory rather than on-site systems has been tested. Accreditation typically fails all testing requirements (such as limited power testing) or fails to meet all structural requirements. An example of UL approved batteries is shrink wrapped batteries that are installed in devices and cannot be replaced by users.

International safety regulations

The European Union and some countries have accepted IEC62133 as a requirement for batteries used domestically. IEC62133 is a simpler specification. It accepts UN38.3 testing as an acceptable certification method. Table 3 lists the battery tests implemented by IEC 62133.

Table 3, IEC 62133 testing

As shown in the table, the test content of IEC 62133 is half that of UL2054, and it is easier to pass because it does not require a single fault on the battery.

Other regulations

Several countries do not accept UL2054 or IEC62133 certification when it comes to allowing batteries to be shipped to their domestic markets - they have their own standards. India needs to conduct testing in its country according to the IS16046 specification, which is similar to IEC 62133. But they do not believe that meeting the IEC62133 regulations is enough. Batteries require BIS (Bureau of Indian Standards) certification. The BIS process is extremely challenging, especially when searching for battery testing laboratories in India and coordinating the completion of testing. Obtaining certification takes six months or more. It is best for battery manufacturers to coordinate with third-party laboratories or logistics to obtain BIS certification.

GOST certification in Russia is easier to obtain. It does not need to be tested domestically in Russia. Compliance with the IEC62133 standard should be sufficient to obtain a certificate from Russia, with a certification period of approximately one month.

South Korea needs to conduct domestic testing to obtain KC certification. This test is based on the IEC 62133 standard and takes approximately three months to obtain certification.

Obtaining TISI certification from Thailand is another complex process. It needs to be tested domestically based on the TIS 2217-2548 specification, which is also similar to IEC62133. The entire process may take over six months. TISI still needs to go to the factory for inspection.

Japan allows self certification through registration within its own country. This test is based on the revised version of the ministerial regulations for determining technical standards for electrical appliances (lithium-ion secondary batteries).

Chinese Mainland requires battery test to comply with GB 31241-2014. This specification is different from other standards, so it needs to be carefully evaluated when designing battery products for Chinese Mainland.

Taiwan, China, China also requires a BSMI certified laboratory to test the battery products entering the region to meet its standards.

sign

Most of these certifications require specific markings on the labels. If required, Table 4 shows the markings that need to be used.

Table 4, Regulatory Mark List

summary

Although battery regulations may seem complex at first glance, the situation can be simplified by asking oneself, ‘Where are batteries intended to be used and in which country?‘. By mastering this, one can determine which regulations to follow. Various regulations are similar, but they all attempt to test the safety of batteries when they are not used correctly.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |