Teach you how to analyze the cause of chip damage

Time:2023-07-19

Views:822

Can‘t the board be debugged for no reason? Burning chips often causes damage? Is the yield too low? Is the chip too fragile? Or is it our improper operation? Perhaps by looking below, you can find the true cause of the problem.

I think everyone has encountered such a problem to some extent. The chip in hand somehow cannot be burned into the program, and after a long time of work, the reason cannot be found. For developers, although it is just a matter of spending a few taels more money to exchange for a chip, it is also quite annoying. For mass production, this situation is not a small problem that often occurs. Here are some small details that may damage your chip, which may be helpful for you who are struggling with chip replacement or struggling with yield.

1. Power supply voltage

You may laugh when you see this. The chip power supply on my system board is LDO output, which is very stable. How could it burn the chip. This starts with two ways to write programs for chips: on board burning and on board burning.

For individual users or certain specific industries, such as automotive electronics, most of them are used for board burning,

Figure 1 On board burning

Another method commonly used for mass production in factories is the firing method, as shown in the following figure.

Figure 2 Seat Burning

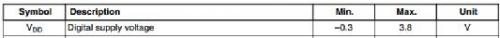

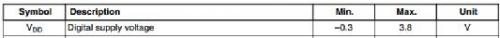

For many development boards or system boards designed by ourselves, the VCC for debugging interfaces is usually directly pulled out of the chip power supply pin. If the programmer‘s power supply is unstable, it is easy to cause overvoltage damage to the chip. The following figure shows the power supply voltage range of an MCU:

If the power supply voltage of the programmer is inaccurate or unstable beyond this range, the chip will be easily damaged.

Not to mention burning, the chip is directly powered by the programmer. If the programmer‘s power supply is unstable, the yield of burning the chip will become your nightmare.

2. Chip encryption

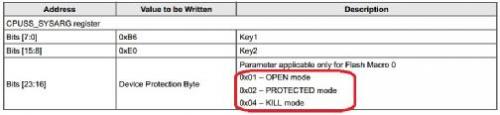

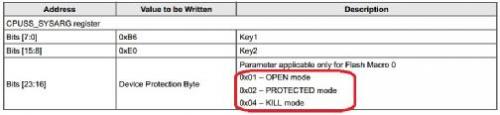

It is easy for ordinary developers to overlook the important function provided by chips, but when your product is about to sell well, this function becomes particularly important. The encryption function can effectively prevent your chip code from being plagiarized. The chip encryption level generally has 3 levels, and I think the Cypress chip manual provides a relatively clear explanation.

OPEN: The chip is not protected, which means that the software you burn into the chip can be directly read by counterfeiters.

Protected: The chip has read protection, which means that no one can read the data in the chip, but the chip can be erased and can be used again after erasing.

KILL: Your chip has been "killed", just like the previous level of protection, no one can read the chip data, but this time, the entire chip erasure does not work, and your chip cannot be burned again, but it is not really "dead". It can also run programs that are burned in.

It should be noted that these protections generally take effect only after re energizing.

If you set the encryption bit of the chip to KILL before waking up and writing the program, congratulations, you can switch to a new chip.

Another interesting situation occurs in mass production, where due to various factors, chips are sometimes interrupted halfway through the burn, while some chips have encryption bits that happen to be in the first part of the burn file. For some burners, they may burn directly in the order of the burn file, resulting in the chip being KILL. However, due to the burn interruption, the program in the second part has not been burned yet, So this chip is really useless. A more reliable burning scheme is to burn the encrypted bit at the end, which can effectively avoid accidental chip lock caused by burning interruption.

3. Programming High Voltage

Some OTP (One Time Programmable) chips may need to program high voltage to write data. Although it is high voltage, many of them are around 6 or 7V, and even higher, it can be over ten volts. This level of voltage is relatively safe for us, but for many chips, it is already considered high voltage. Even some OTP chips that require this voltage to program cannot withstand it for a long time, Therefore, some chips may specify the maximum time for high-pressure loading, and once this limit is exceeded, the OTP area may be permanently damaged. Some programmers provide an output function for programming high voltage, automatically switching on and off the programming voltage during the burning process. However, for programmers who do not provide programming high voltage, it is important to be careful not to lose focus during programming, and to disconnect the programming high voltage in a timely manner.

In addition, there are many other factors that can damage your chip, such as whether static electricity protection is in place, whether the humidity and temperature of chip storage meet the requirements, whether the temperature of chip welding is too high, and to improve the yield of burning and writing, it is necessary to work from multiple aspects. However, the above details that are not easy to pay attention to cannot be ignored.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |