Reduce component costs with high-voltage battery management architecture

Time:2022-11-24

Views:1543

The two 400V batteries can be connected in series during charging (800V in total) to reduce the charging time, while they can be connected in parallel during driving (400V). So as to ensure that the capacity and range of standard high-capacity 400V transmission system components (such as inverter and on-board charger) will not be affected when they are used.

800V HVBMS architecture using TPL

This method allows rapid charging and reuse of existing 400V solutions, which is the best of both worlds for designers. The cost is under control, and faster charging will bring huge competitive advantages and attract consumers.

Key Systems of xEV Power

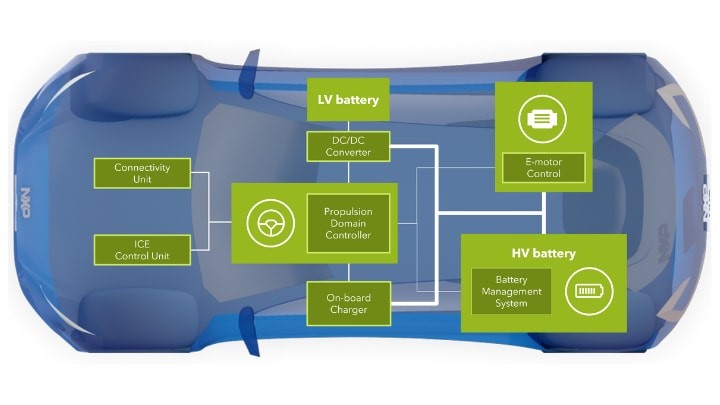

The figure above shows the key systems of electric vehicle power. The figure shows the main high-voltage (HV) battery and its management system. The low voltage (LV) side is a lead-acid battery or a lithium battery, usually 12~14 V, which can provide the lower voltage required for interior lighting, door locks, navigation and driving assistance systems. The 12V battery can also be used as a backup power supply to take over key safety functions, such as steering, when the main high-voltage battery cannot supply power.

Learn more about innovative solutions that simplify EV development.

Any solution has an uncompromising standard, regardless of the cost. The vehicle must be functionally safe and must comply with all relevant safety and environmental regulations wherever it is sold. In addition, the car also needs to provide the functions and advantages that consumers admire, which means that the car must have sufficient endurance, performance, comfort and fashion sense.

How can designers reduce costs while meeting these parameter requirements?

You should first view the components on their bill of materials (BOM). Is the bill of materials the simplest? Can a component be replaced with a cheaper, more integrated alternative product? Will replacing a component bring other benefits, such as reducing the number of external components required with processors or systems on chip (SoC)?

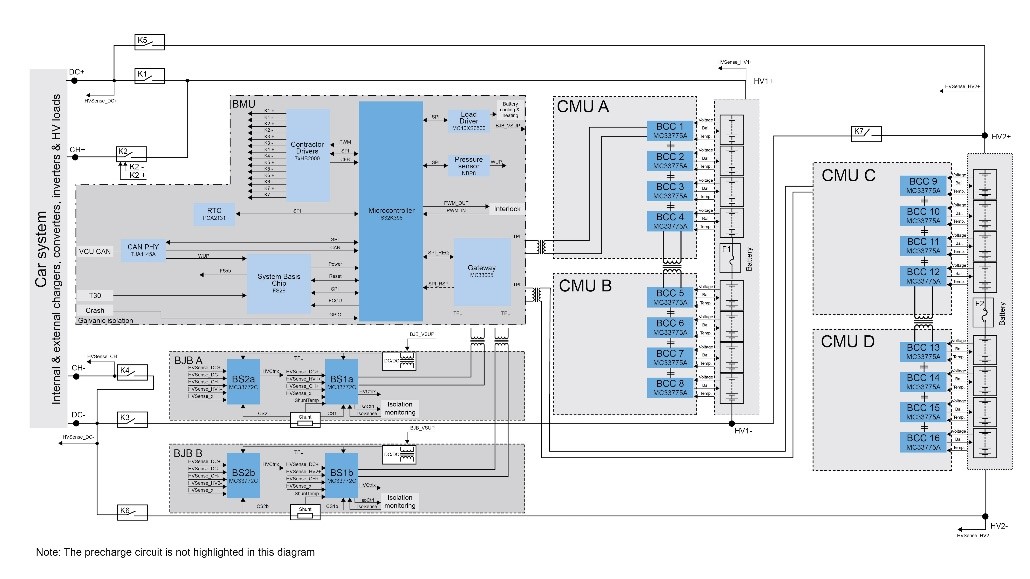

For example, the analog front end (AFE) is an important part of the battery management system (BMS). It can not only obtain data from the battery unit, but also digitize and adjust the obtained data. By using highly integrated AFE (such as NXP MC33775A, 14 channel battery unit controller), you can reduce the number of cables required, reduce the cost of BOM and reduce the overall system cost.

The designer can then consider production and manufacturing processes. Can you choose components that can be assembled automatically to reduce costs?

In addition, can we save costs through modular design that can be reused and expanded across multiple models? This method is now very common, with a unified vehicle platform to support various models. In other words, auto manufacturers can not only provide consumers with a variety of choices, but also will not cause a surge in development costs, and even benefit from economies of scale of component costs. For example, Volkswagen has introduced NXP‘s BMS system into its MEB platform, greatly reducing the difficulty in promoting the system in multiple models. Volkswagen plans to launch as many as 75 all electric vehicles to the market before January 2029. The adoption of the BMS system will bring great advantages.

More specifically, BMS will collect analysis data from the battery to determine the SoC and SoH of the battery. BMS can use this data to manage the battery for high performance, high battery life, and diagnosis of any problem.

Want more information? Watch the BMS introduction video.

NXP Automobile Charging

In this article, we studied how designers can reduce the cost of electric vehicles, especially the cost of components related to BMS. Although these general principles are applicable to all kinds of electric vehicles, they may be particularly important when turning to the 800V architecture, because the 800V architecture may have higher component costs and fewer alternative sources of components.

To learn more, please download NXP‘s white paper.

Author:

Emiliano Mediavilla Pons

Emiliano Mediavilla Pons, from the Tier 1 market of the automotive industry chain, joined NXP in 2015 as the product definition and functional safety architect of the solid-state lighting business. Since 2018, Emiliano has joined the BMS team as the chief functional security architect of the application team. Emiliano has been a system, product, and functional safety architect in the automotive industry for the past 14 years. Emiliano holds a bachelor‘s degree in electrical engineering from the University of Oviedo, a master‘s degree in automotive electronics and electrical engineering from the Polytechnic University of Catalonia, and a master‘s degree in business administration from the University of Oviedo.

Konrad Lorentz

Konrad Lorentz holds a bachelor‘s degree in international project engineering from Reutlingen University, Germany. In 2020, he joined NXP with a paper on "automobile value chain" and currently serves as the product manager of BMS marketing team.

Konrad Lorentz holds a bachelor‘s degree in international project engineering from Reutlingen University, Germany. In 2020, he joined NXP with a paper on "automobile value chain" and currently serves as the product manager of BMS marketing team.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |