Three methods of using brushless DC motors to accelerate the design cycle

Time:2024-03-05

Views:268

The world is striving to reduce power consumption, and the momentum is getting stronger. Many countries/regions require household appliances (as shown in Figure 1) to meet the efficiency standards established by relevant organizations such as the China Institute of Standardization (CNIS), Energy Star in the United States, and Blue Angel in Germany. In order to meet these standards, more and more system designers are abandoning simple and easy-to-use single-phase AC induction motors in their designs and instead adopting more energy-efficient low-voltage brushless DC (BLDC) motors. In order to achieve longer service life and lower operating noise, designers of small household appliances such as sweeping robots have also turned to using more advanced BLDC motors in many of their systems. Meanwhile, the advancement of permanent magnet technology is continuously simplifying the manufacturing of BLDC motors, providing the same torque (load) while reducing system size, which can also improve efficiency and reduce system noise.

Figure 1: Common household appliances

Designing systems using BLDC motors is challenging as it typically requires complex hardware and optimized software design to provide reliable real-time control. One option to accelerate the design cycle is to use BLDC motor modules provided by professional suppliers, but these modules have not been optimized for specific system requirements. Therefore, in order to build optimized high-performance systems to meet specific application requirements, it is still necessary to have a deep understanding of motor design and control, even when using modules. In this article, I will introduce three methods that not only accelerate the design of BLDC motor systems, but also provide more intelligent and compact energy-saving solutions.

Method 1: No programming required, no sensor control

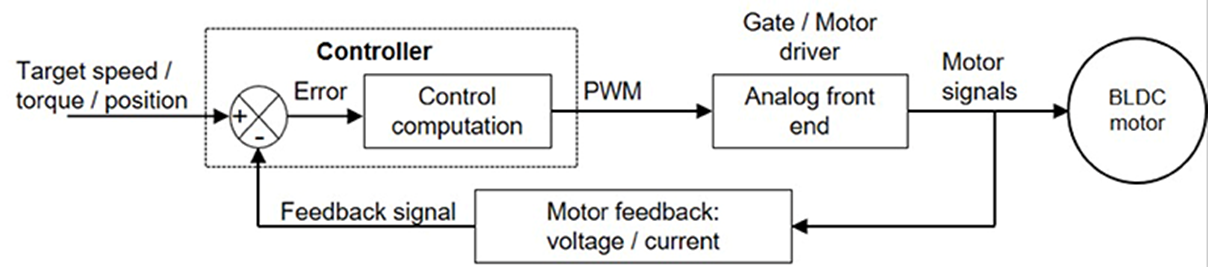

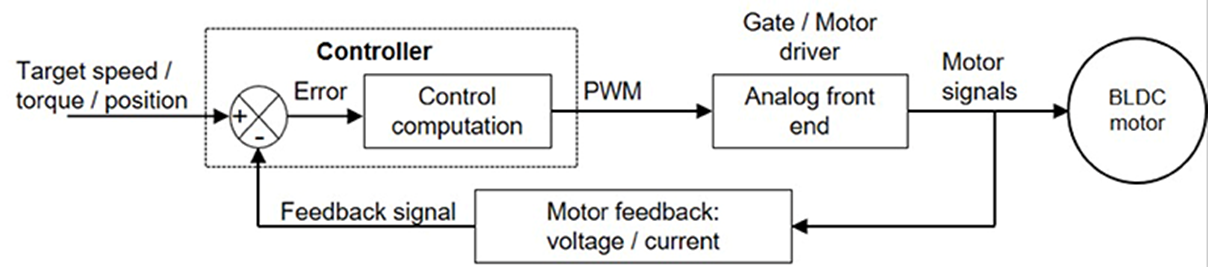

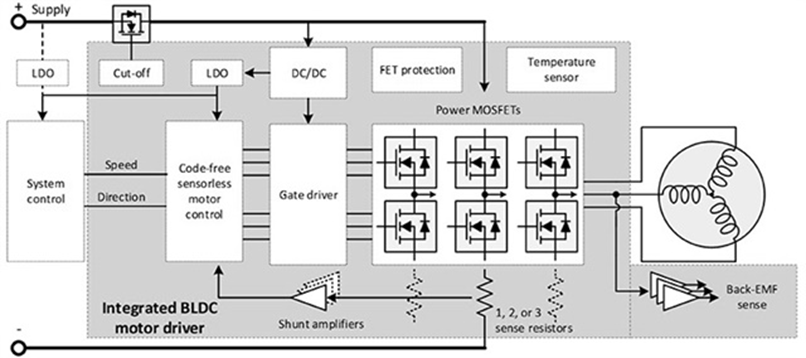

The motor driver that does not require programming includes a built-in control commutation algorithm, so there is no need for the development, maintenance, and certification of motor control software. These motor drivers typically obtain feedback from the motor (such as Hall signals or motor phase voltage and current signals), calculate complex control equations in real-time to determine the next motor drive state, and provide pulse width modulation signals to analog front-end components such as gate drivers or metal oxide semiconductor field-effect transistors (MOSFETs) (as shown in Figure 2).

Figure 2: Typical sensorless BLDC motor system

When using a motor driver with integrated sensorless control function (such as the MCF8316A motor driver with field oriented control (FOC) function) for real-time control, there is no need for Hall effect sensors in the motor, which can improve system reliability and reduce total system cost. A motor driver that does not require programming can also manage important functions (such as motor fault detection) and implement protection mechanisms, making the entire system design more reliable. These devices can come with pre certification control algorithms implemented by certification agencies such as the Insurance Companies Laboratory in the United States, allowing original equipment manufacturers to shorten the design time of their household appliances.

Method 2: Use the intelligent motor control function to easily tune the motor

The system performance parameter requirements, such as speed, efficiency, and noise, are difficult to solve by tuning the BLDC motor. This problem can be solved by developing a sensorless trapezoidal control algorithm, where the commutation is determined by the back electromotive force voltage of the motor, so that the adjustment operation is not limited by the motor parameters. The integrated motor driver (such as MCT8316A) with sensorless trapezoidal control function can provide optimized system performance without the need for complex interface connections to microcontrollers. In addition, please note that during the motor tuning process, the integrated motor driver will provide feedback signals, such as the motor phase voltage, current, and motor speed displayed on the oscilloscope.

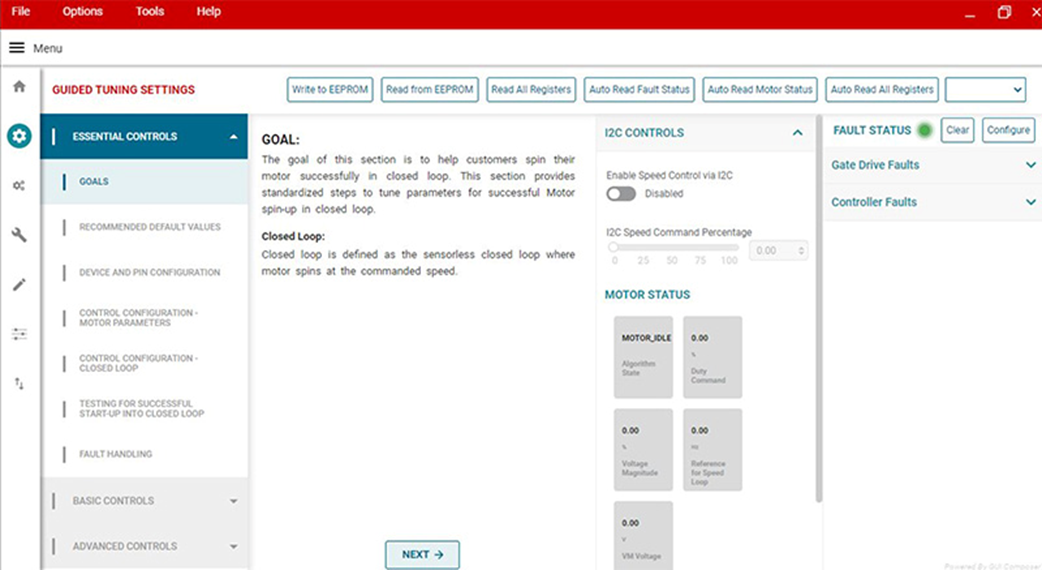

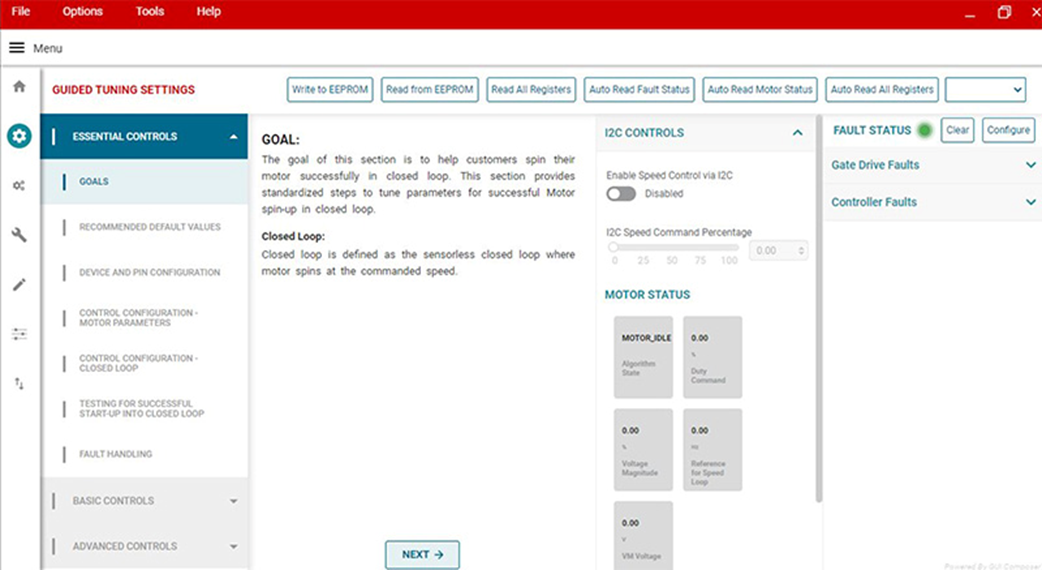

In the sensorless FOC algorithm, due to the integration of advanced control technology, motor tuning can be significantly accelerated, for example, by self measuring motor parameters or automatically executing control loop tuning to accelerate speed. The guided tuning graphical user interface (GUI) provides default motor startup options (as shown in Figure 3), which helps to smoothly complete the tuning process and quickly rotate the motor. Non programmable motor drivers (such as MCF8316A for FOC and MCT8316A for trapezoidal control) include multiple configurable options for motor start, closed-loop, and motor stop operations. With these options, motor performance can be optimized in just a few minutes, significantly shortening the design cycle.

Figure 3: Guided tuning GUI

Third method: Reduce size

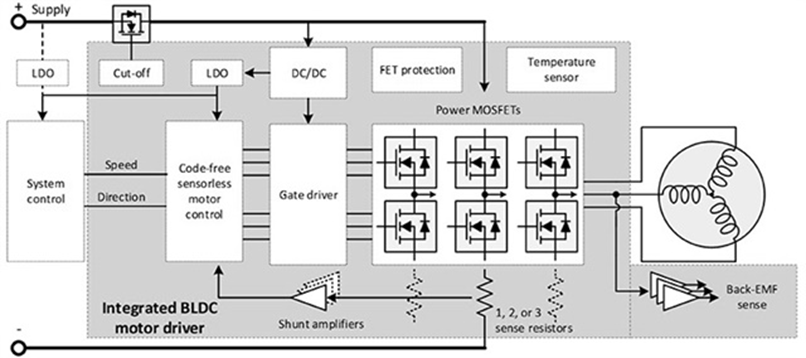

For many system designers, the hardware construction work of BLDC systems is very challenging. A typical system requires gate drivers, MOSFETs, current sensing amplifiers, voltage sensing comparators, and analog-to-digital converters. Most systems require a dedicated power architecture (including devices such as low-voltage voltage regulators or DC/DC voltage regulators) to power all components on the board. The integrated BLDC driver combines all these components, providing a compact but easy-to-use solution, as shown in Figure 4.

Figure 4: Fully integrated BLDC motor solution

The motor driver with integrated control functions includes protection functions, such as overcurrent and overvoltage protection for MOSFETs, as well as temperature monitoring, allowing designers to easily provide powerful solutions. For motor applications with a power consumption of less than 70W, such as sweeping robots, household ceiling fans, or pumps used in washing machines, devices with integrated MOSFETs can be chosen to further reduce the space on the fabric board. MCF8316A and MCT8316A devices support peak currents of up to 8A in 24V applications. For high-power applications, power MOSFETs can be placed on the board to integrate gate drivers and motor control functions into a single chip.

The concepts discussed in this article help accelerate the system design cycle while providing a more compact and intelligent BLDC motor system. With the help of BLDC motor drivers such as MCF8316A and MCT8316A that do not require programming or sensors, optimized high-performance real-time control systems can be quickly designed. These devices can provide up to 70W of power for 24V applications. With integrated intelligent control technology, both motor drivers are easy to tune and can be used to achieve high-performance and reliable system solutions, making them an ideal choice for building the next low-voltage energy-saving system based on BLDC.

About Texas Instruments (TI)

Texas Instruments (TI) (NASDAQ stock code: TXN) is a global semiconductor company dedicated to designing, manufacturing, testing, and selling analog and embedded processing chips for industrial, automotive, personal electronics, communication equipment, and enterprise systems markets. We are committed to making electronic products more economical and practical through semiconductor technology, and creating a better world. Nowadays, every generation of innovation is built on the foundation of the previous generation, making our technology smaller, faster, more reliable, and more affordable, thus achieving the widespread application of semiconductors in the field of electronic products. This is the progress of engineering. This is exactly what we have been doing for decades and even now.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |