How to transition more easily to sine control and accelerate the design process for three-phase brushless DC motors

Time:2024-02-23

Views:323

Brushless DC (BLDC) motors are widely favored in various applications, such as computer cooling fans, disk drives, wireless power tools, electric bicycles, and turntables for record players. As prices continue to decline, motors will have even wider applications, while the most cost sensitive applications are another matter. However, with the increasing demand, people are also increasingly demanding that BLDC motors operate smoother, more efficient, and quieter.

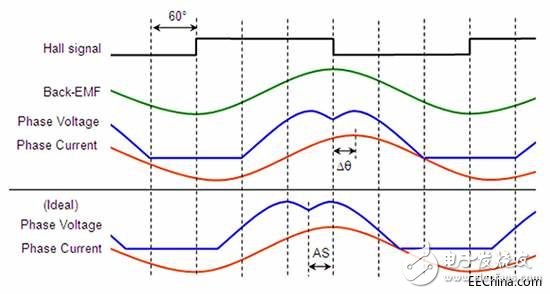

Figure 3: Actual sine control implementation does not use pure sine wave voltage to drive each phase. On the contrary, using a saddle voltage will generate a sine wave differential voltage between the two terminals, with a phase offset of 120 ? Change direction. In this way, the torque and speed under a given voltage will be greater, and the efficiency will also be improved.

After calculating the motor angle, the following code (accessible query table) can be used to calculate the duty cycle:

Figure 3: Actual sine control implementation does not use pure sine wave voltage to drive each phase. On the contrary, using a saddle voltage will generate a sine wave differential voltage between the two terminals, with a phase offset of 120 ? Change direction. In this way, the torque and speed under a given voltage will be greater, and the efficiency will also be improved.

After calculating the motor angle, the following code (accessible query table) can be used to calculate the duty cycle:

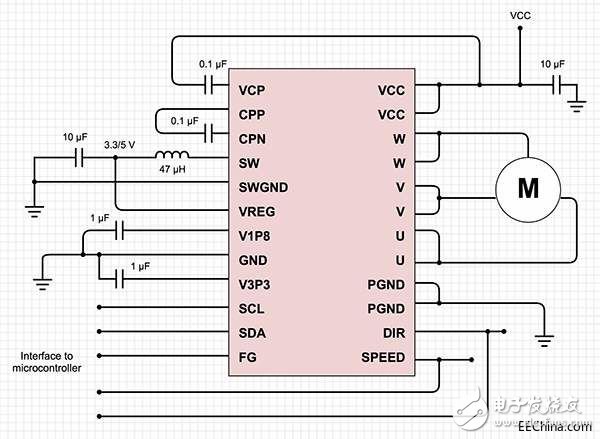

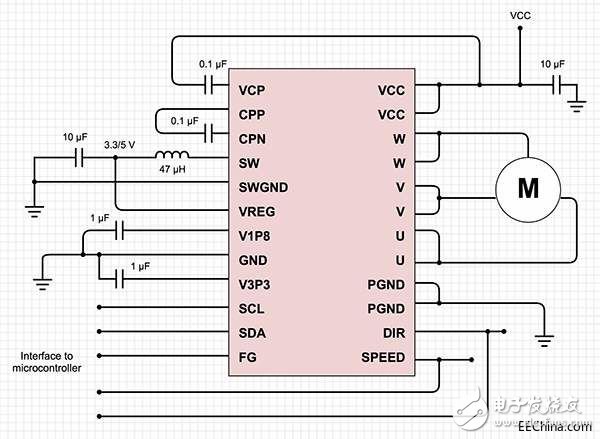

Figure 5: Texas Instruments DRV10983 enables designers to create a sinusoidal controlled BLDC motor system, which includes a low-cost MCU and a small number of passive components.

Figure 5: Texas Instruments DRV10983 enables designers to create a sinusoidal controlled BLDC motor system, which includes a low-cost MCU and a small number of passive components.

Although sine control is the best way to achieve these goals, compared to more traditional trapezoidal control techniques, this type of control increases cost and complexity. This article will discuss the basic principles of BLDC motor control and the reasons for using sine control instead of trapezoidal control. This article will also introduce some ready-made commercial solutions, including integrated motor drivers and controller chips, which can be used to transition more easily to sine control and accelerate the design process.

Basic principles of BLDC motors

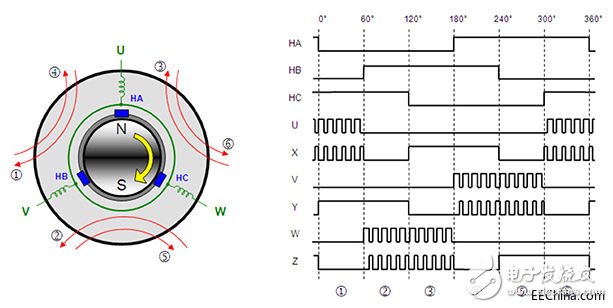

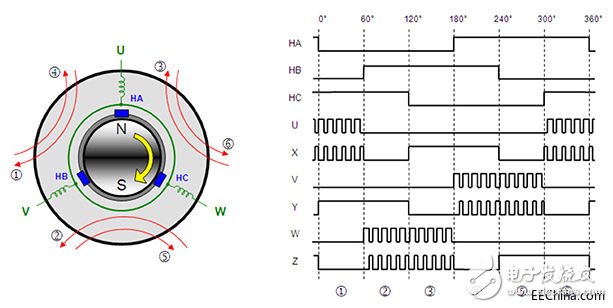

The BLDC motor eliminates the requirement of using a mechanical commutator by setting up a reverse motor; The winding becomes the stator, and the permanent magnet becomes a part of the rotor. The winding is usually powered by a six MOSFET bridge controlled by pulse width modulation (PWM), which turns in control order to generate a rotating magnetic field, thereby "dragging" the rotor around it and driving the connected load (Figure 1).

Figure 1: The power supply method of BLDC motor is to sequentially excite the windings using PWM signals. The duty cycle of the PWM signal is proportional to the driving voltage. In this figure, "U", "V", and "W" are windings, and "HA", "HB", and "HC" are position sensing Hall effect sensors.

The commutation is determined by the relative position of the rotor and stator, which is measured by Hall effect sensors or by the amplitude of the back electromotive force (EMF) generated during motor rotation (limited to sensorless motors).

There are currently three electronic commutation control schemes: trapezoidal, sinusoidal, and field oriented control (FOC). The implementation cost of FOC is high and it is specifically designed for high-end applications, so this article will not discuss it.

For many applications, trapezoidal controlled BLDC motors are the best solution. This type of motor has a compact structure, reliable performance, and rapidly decreasing price, making it particularly suitable for many small motor applications, including automobiles, white goods, and computers.

In addition, trapezoidal technology is the easiest to implement and therefore the most popular. The motor is powered by DC for each phase, every 60 ? Change direction. The phase drive is set to "high", "low" or kept in a floating state.

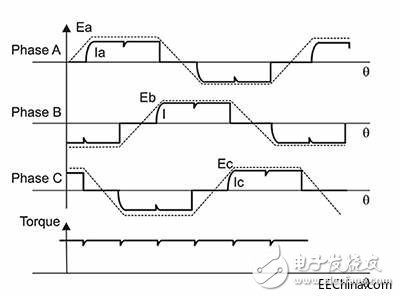

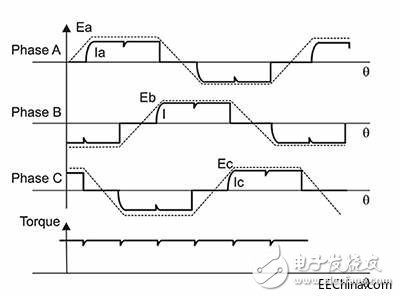

In theory, such a system can generate smooth and constant torque. In fact, the current of a specific phase cannot instantly change from low to high. On the contrary, the resulting rise time generates ripples in the output that are consistent with the steering timing (Figure 2).

Figure 2: The waveform of a three-phase BLDC motor using trapezoidal control. Please note that the driving current of each phase slightly decreases when turning occurs. This will cause ripples in the motor torque. The dashed line records the trapezoidal diagram of the back electromotive force in each phase, where the zero crossing point coincides with the midpoint of the phase‘s floating period.

Torque ripple is not the only drawback of trapezoidal control BLDC motors. Another drawback is electrical and acoustic noise. An important source of noise is the fast switching DC current that supplies power to each phase. From an electrical perspective, this noise will heat up the winding and reduce efficiency. From an acoustic perspective, the buzzing sound frequency generated by the switching frequency and its harmonics may not be very high, but it is very harsh.

(For detailed information on the operation of BLDC motors and trapezoidal control schemes, please refer to the database article "How to Power and Control Brushless DC Motors".)

Implement sine control

Sinusoidal control is very complex, and few engineers can implement the system solely based on basic principles. A better approach is to utilize the knowledge of chip suppliers and BLDC motor design and development kits. The FRDM-KE04Z of NXP is an example.

It utilizes Kinetis KE04 ARM ® Cortex ®- M0 MCU runs sine algorithm. Due to the control circuit design being based on a common BLDC driver chip, the implementation difficulty is further reduced. These devices typically integrate PWM control and power electronics into one chip and provide interfaces to external MCUs. Integrating MCU with other devices only requires some additional passive components to form a complete circuit.

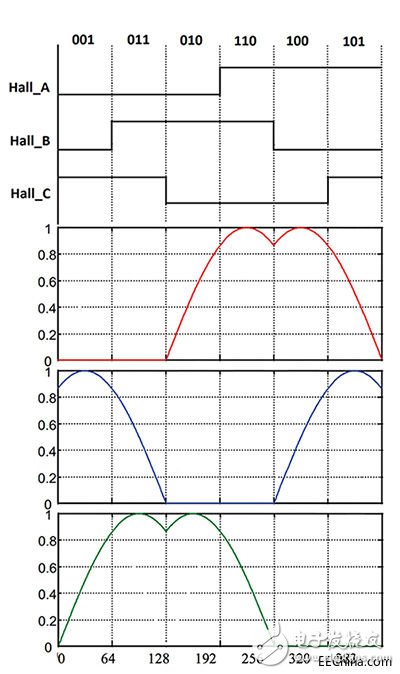

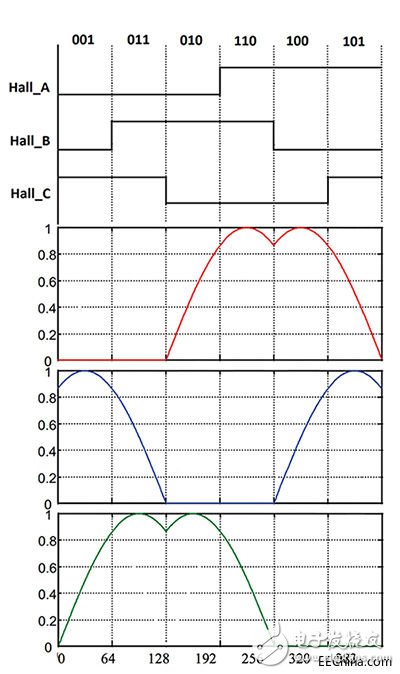

Sine substitution method: "saddle" diagram

Pure sinusoidal driving voltage is rarely used in practice because the efficiency of generating voltage for each motor terminal is relatively low compared to grounding. A better method is to generate a sinusoidal differential voltage between phases, with a phase offset of 120 ? Change direction. The implementation method is to change the PWM duty cycle relative to ground (as well as the driving voltage) by using a "saddle" diagram (instead of a sine) (Figure 3). Subsequently, the phase current of the driving motor follows a pure sine wave variation of the phase to phase voltage.

The saddle plot method has two advantages: firstly, the maximum differential voltage generated is higher than the voltage that can be generated by a pure sine signal, so the given input torque and speed are also greater. Secondly, each terminal outputs zero for 1/3 of the time, further reducing switching losses in the power stage.

A complexity of the sine control method lies in precisely controlling the duty cycle based on the motor angle required to form a saddle voltage input. This even becomes more difficult during high-speed rotation. The main challenge is that the motor position can only be accurately determined six times per revolution, and one of the magnetic poles of the rotor passes through one of the three Hall sensors. For example, a common solution for FRDM-KE04Z is to multiply the motor angular velocity by partial T and assume that the motor velocity is constant, in order to estimate the motor angle ("mtrAngle") between Hall sensors.

Then use a query table to determine the PWM duty cycle for a specific angle. In FRDM-KE04Z, the query table provides the duty cycle for each angle of motor rotation (actual 384 increments).

The following code snippet illustrates how FRDM-KE04Z calculates angles (clockwise rotation) 1:

deltaAngle = F32Add(deltaAngle,F(xiàn)32Abs(velocityAct));

if (deltaAngle 》= DELTANGLE_MAX) //limit deltaAngle range into

{ [0,64]

deltaAngle = DELTANGLE_MAX;

}

mtrAngle = HallTableCW[motorPosition];

mtrAngle += (tU16)((deltaAngle) 》》 12);

mtrAngle += (tU16)advanceAngle;

if (mtrAngle 》= 384)

{

mtrAngle -= 384;

}

dutyCycleU16A = (Frac16)(((Frac16)dutyCycleU16 * (Frac16)SinusoidalWaveTable[mtrAngle]) 》》 8);

if (mtrAngle 《 128)

{

dutyCycleU16B = (Frac16)(((Frac16)dutyCycleU16 * (Frac16)SinusoidalWaveTable[mtrAngle + 256]) 》》 8);

}

else

{

dutyCycleU16B = (Frac16)(((Frac16)dutyCycleU16 * (Frac16)SinusoidalWaveTable[mtrAngle - 128]) 》》 8);

}

if (mtrAngle 》= 256)

{

dutyCycleU16C = (Frac16)(((Frac16)dutyCycleU16 * (Frac16)SinusoidalWaveTable[mtrAngle -256]) 》》 8);

}

else

{

dutyCycleU16C = (Frac16)(((Frac16)dutyCycleU16 * (Frac16)SinusoidalWaveTable[mtrAngle + 128]) 》》 8);

}

Code List: Required code for calculating the motor angle and PWM duty cycle of the FRDM-KE04Z development kit. (Code source: NXP)

Code List: Required code for calculating the motor angle and PWM duty cycle of the FRDM-KE04Z development kit. (Code source: NXP)

This type of method utilizes the incidental effects of using saddle plots. Special note: Due to the voltage value of a specific phase being zero for one-third of the time, there is no need to query during this period, which requires less processor resources and allows for the use of more common low-cost MCUs in applications.

The disadvantage of this method is that when the motor accelerates rapidly during the startup phase, the interpolation of motor speed between Hall sensors is likely to be inaccurate. This can lead to uneven torque response.

A common solution adopted by ROHM Semiconductor‘s BD62011FS fan motor controller to address this issue is to start the motor in trapezoidal control mode and switch to sine control after reaching a specific speed (usually 5-100 Hz), resulting in higher interpolation accuracy.

Rohm‘s equipment is mainly aimed at controlling BLDC motors equipped with Hall sensors. The chip adopts PWM control and sinusoidal commutation logic of high-voltage and low-voltage MOSFETs. It can operate within the input range of 10 to 18 V and provides an output range between 2.1 and 5.4 V (up to 1 W). The target applications include air conditioning, water pumps, and white goods.

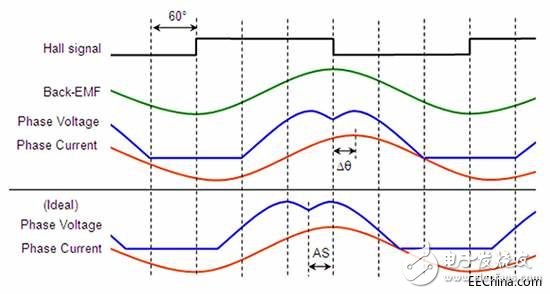

Another design challenge is the phase delay between the given phase driving voltage and the generated sine wave current, which typically occurs in non compensating BLDC motors. The motor can operate normally, but its efficiency will decrease, which will first defeat the goal of achieving a sinusoidal control scheme. The reason for this low efficiency is not the phase delay between the driving voltage and phase current, but the phase delay between the phase current and the sinusoidal back electromotive force.

Fortunately, many driver chips, including ON Semiconductor‘s LV8811G power MOSFET driver, allow designers to introduce a leading phase angle in the sinusoidal driving current, ensuring that its peak is consistent with the peak of the back electromotive force. The leading phase angle is usually set to increase linearly with the input voltage, which determines the motor speed (Figure 4).

Figure 4: In a non compensated sine controlled BLDC motor, the phase current delays the back electromotive force, resulting in low efficiency (as shown in the above figure). Many driver chips include advanced phase angle, which allows designers to set the current phase to be consistent with the back electromotive force (as shown in the figure below).

LV8811G is a three-phase BLDC motor driver controlled by a single Hall sensor and adopts sinusoidal control. Direct PWM pulse input or DC voltage input can be used to control motor speed.

When using LV118811G, designers can set the initial conditions through the voltage divider resistors on pins PH1 and PH2: the speed at which the phase angle starts to lead and the gradient of the leading phase angle slope. Afterwards, the internal logic of the chip determines the leading phase angle of the given speed based on a predetermined formula.

Sensorless BLDC sine control

Sinusoidal control can also be achieved through sensorless BLDC motors. The operation of these motors is similar to that of motors using Hall effect sensors, except that the position information is obtained by measuring the back electromotive force.

For example, DRV10983 from Texas Instruments is designed for sinusoidal control of sensorless BLDC motors. The chip integrates power electronic devices, which can connect to external MCUs and provide up to 2 A of continuous driving current. Sine control is achieved through the use of the company‘s proprietary control scheme.

In this scheme, the commutation control algorithm continuously measures the motor phase current and regularly measures the supply voltage. Then, the device uses this information to calculate the back electromotive force and motor position. The motor speed is determined by the number of zero crossings of a phase‘s back electromotive force per unit time. The chip also allows for advanced phase angle to adjust phase current and back electromotive force, thereby achieving maximum efficiency.

DRV10983 is specifically designed for cost sensitive, low noise, and low external component counting applications (Figure 5).

summary

BLDC motors are gradually becoming a substitute for traditional brushed motors due to their advantages in performance and reliability. For many applications, trapezoidal control can meet usage expectations, but if the task of designers is to improve efficiency, reduce electrical and acoustic noise, and improve torque transmission, sinusoidal control should be considered.

Although sine control increases complexity and cost, development tools, functional MCUs, and integrated driver ICs have greatly simplified the design process, making sine control more practical and simple. Moreover, the flexibility of development tools and the adaptability of driver ICs enable designers to fine tune the applied motors and pay more attention to product differentiation.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |