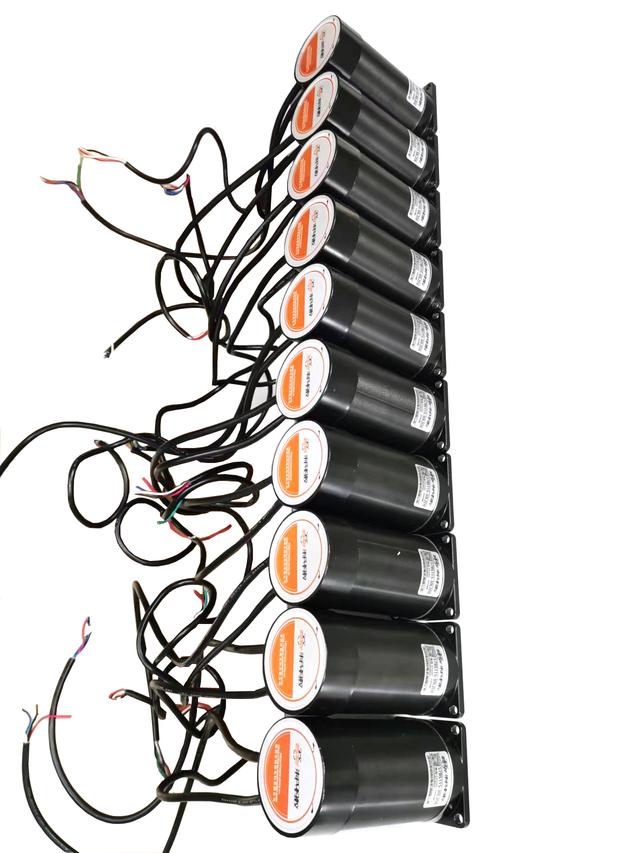

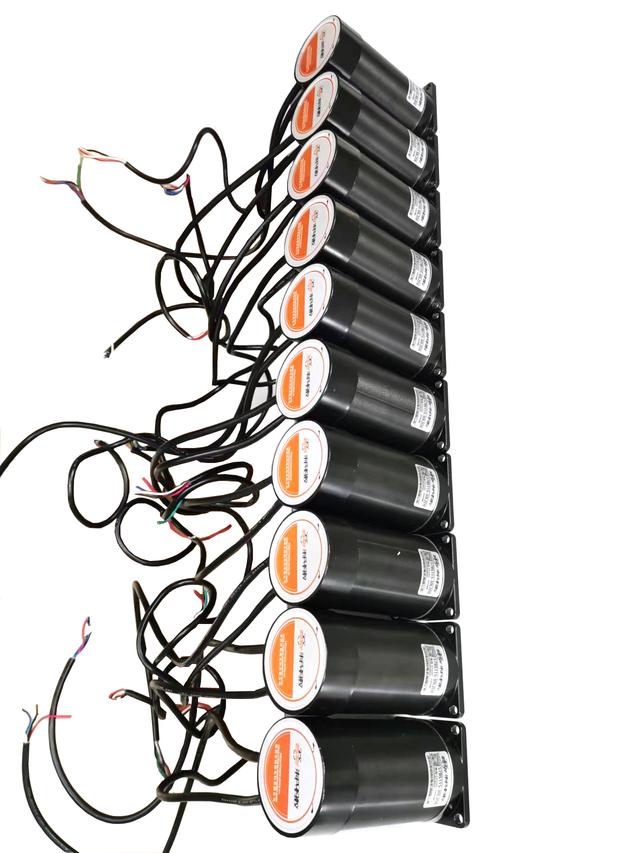

Selection and precautions for DC brushless motors

Time:2024-01-26

Views:353

Brushless DC motor is a typical electromechanical integrated product composed of the motor body and driver. Compared with brushless motors, brushless motors do not have the commutator set up for commutation in traditional motors. Therefore, brushless motors are structurally simpler and can achieve higher operating speeds and less mechanical wear. In addition, brushless motors can achieve more precise speed control and operation curve control by adjusting the parameters of the controller. The application range of brushless motors is very wide, including household appliances, automobiles, robots, aerospace, office automation equipment, and so on. Due to its high efficiency and superior performance, brushless motors have become one of the mainstream in modern motor technology.

High speed performance: DC brushless motors have higher stability and lower noise during high-speed operation.

High speed performance: DC brushless motors have higher stability and lower noise during high-speed operation.

When choosing a DC brushless motor, the following points should be noted:

When choosing a DC brushless motor, the following points should be noted:

Compared to traditional brushless motors, DC brushless motors have many advantages:

High efficiency: Due to the lack of brushes and commutators, the mechanical and brush losses of DC brushless motors are smaller, resulting in higher efficiency.

Long lifespan: DC brushless motors do not have brushes and commutators with brushes, so there is no need to replace them due to wear and tear, resulting in a longer lifespan.

Accurate control: DC brushless motors can achieve more precise speed control and operation curve control by adjusting the parameters of the controller.

Wide application range: DC brushless motors can be applied in various fields such as household appliances, automobiles, robots, aerospace, office automation equipment, etc.

Low speed high torque: DC brushless motors have the characteristic of outputting high torque at low speeds, making them suitable for situations that require high starting torque.

Good regenerative braking effect: The rotor of the DC brushless motor is made of permanent magnet material, which can enter the generator state during braking, resulting in better regenerative braking effect.

Small size and light weight: Compared to brushless motors, DC brushless motors have smaller size and lighter weight, making them easy to carry and install.

Good protection: The DC brushless motor adopts a fully enclosed structure, which provides better protection and can prevent dust and moisture from entering the interior of the motor.

In summary, compared to traditional brushless motors, DC brushless motors have advantages such as higher efficiency, longer lifespan, more precise control, wider application range, better low-speed high torque performance, better high-speed performance and regenerative braking effect, and better protective performance.

When choosing a DC brushless motor product, the correct voltage should be selected, and the rated voltage should be selected according to the customer‘s needs to select the driver voltage parameters. It is important to note that the voltage used should not exceed the range specified by the driver during no-load and full load processes.

Secondly, let‘s choose the peak current of the driver. The method for selecting the peak current is to know the rated input current Ir (A) of the motor, so the peak current Ip (A) is ≥ 2Ir. Otherwise, there is no certain engineering margin for the output current of the driver during use. If the rated output power (or maximum output power) Pr (W) and driving voltage Vr (V) of the motor are known, then the peak current Ip (A) is ≥ 4Pr/Vr.

In addition, when choosing a DC brushless motor, temperature changes should be considered. The wider the temperature change, the more expensive the price will be, and it will affect the lifespan of the motor.

In addition, the insulation requirements of the power supply should also be considered. In order to ensure the normal operation of the driver, the insulation resistance of the Hall ground wire and motor winding of the DC brushless motor needs to meet the requirements and be able to withstand a certain breakdown voltage.

The selection of DC brushless motors also needs to pay attention to details, such as the interface type and moment of inertia of the brushless motor. At the same time, it is necessary to ensure that the selected motor is perfectly compatible with your control system to achieve more efficient control.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |