6 key elements of brushless DC motor control, understanding the principles of BLDC and PMSM motors

Time:2024-01-13

Views:388

Motor control plays a major role in achieving these commitments, and understanding the fundamental principles is the first step towards achieving the goals. The key elements of motor control for brushless direct current (BLDC) motor management, and how it improves efficiency while reducing costs, saving space, and improving performance.

1. Different motor types

There are several types of motor control topologies available: brushed, brushless direct current (BLDC), stepper, and induction. The two most closely related types of brushless motors are BLDC and permanent magnet synchronous motor (PMSM).

Brushless motors have become very popular in many applications today because they eliminate the need for motor brushes. These BLDC topologies use commutation logic to move the rotor, making it more efficient and reliable.

The commutation of a brushed motor is generated by the brush/commutator interface. This interface will cause friction and arcing, which will decrease the performance of the brush over time. This friction generates heat and shortens the lifespan of the motor.

Compared to brushless motors, BLDC motors have many advantages. They are energy-saving, smaller, lighter, quieter, more reliable, and more durable. In addition, they provide precise speed control, making them more suitable for variable speed applications.

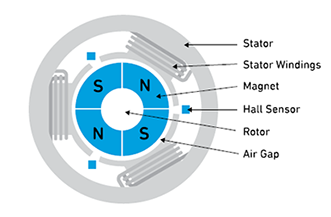

2. Understand BLDC and PMSM motors

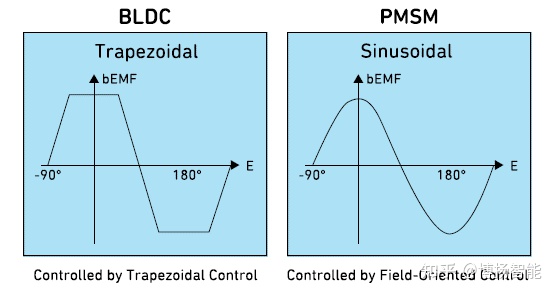

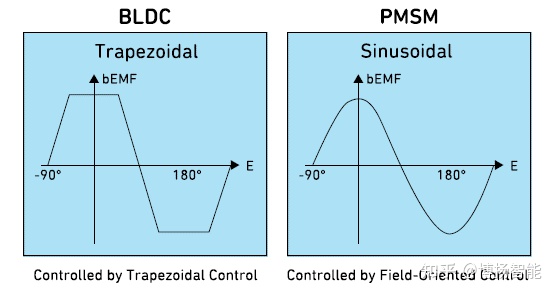

BLDC and PMSM motors operate based on the principle of synchronous motors. The rotor continues to chase the stator during each commutation, so the motor moves continuously. However, the stator windings of these two DC motors have different geometric shapes, resulting in different back electromotive force (BEMF) responses. BLDC BEFM is trapezoidal. The PMSM motor has a sinusoidal BEMF, so the coil winding is wound in a sinusoidal manner. To maximize performance, these motors typically use sine wave commutation.

BLDC and PMSM motors generate BEMF through their windings during operation. In any motor, the electromotive force generated due to motion is called the back electromotive force (BEMF), because the induced electromotive force in the motor is opposite to the electromotive force in the generator.

3. Explanation of magnetic field orientation control

To obtain the sinusoidal waveform for controlling PMSM motors, a Field Oriented Control (FOC) algorithm is required. FOC is typically used to maximize the efficiency of PMSM three-phase motors. The sine controller of PMSM is more complex and cost-effective than the BLDC trapezoidal controller. However, the advantage of this cost increase is that there is lower noise and fewer harmonics in the current waveform. The main advantage of BLDC is that it is easier to control. Ultimately, the choice of which motor is best depends on its application.

4. BLDC and PMSM motors with and without sensors

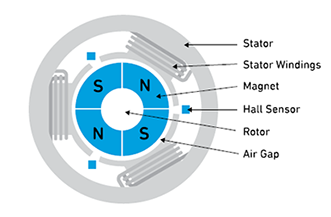

BLDC and PMSM motors can be with sensors or without sensors. Motors with sensors are used for applications that require the motor to start under load conditions. They use Hall sensors embedded in the motor stator. A sensor is essentially a switch, with a digital output equal to the polarity of the sensed magnetic field. Each phase of the motor requires a separate Hall sensor. Therefore, a three-phase motor requires three Hall sensors. Sensorless motors require algorithms to use the motor as a sensor for operation. They rely on BEMF information. By sampling BEMF, the rotor position can be inferred, eliminating the need for hardware based sensors. Regardless of the topology of the motor, controlling these machines requires knowing the rotor position in order to effectively reverse the motor.

5. Motor control software algorithm

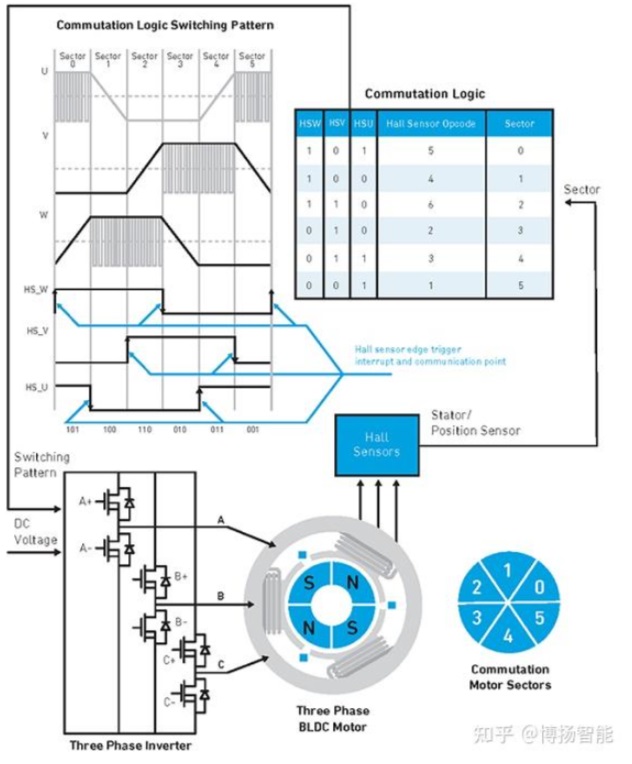

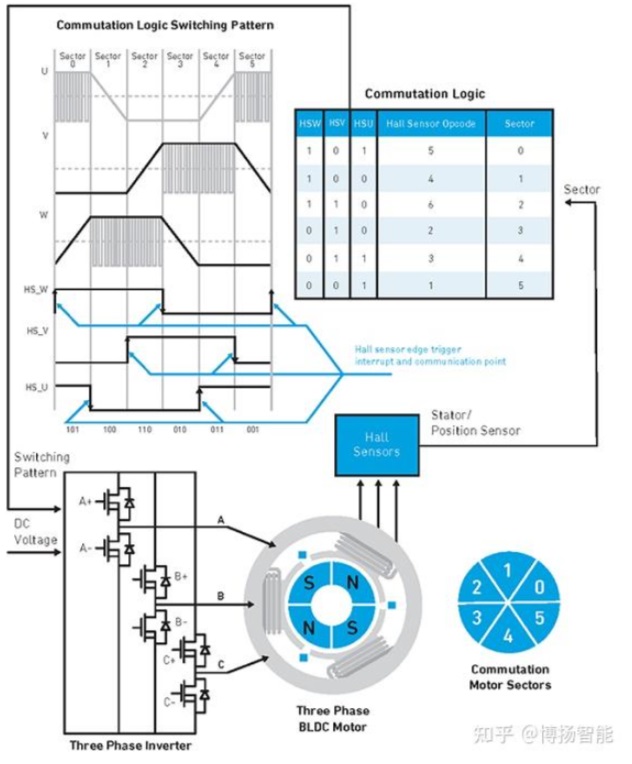

Software algorithms (i.e. a set of instructions designed to perform specific tasks), such as computer programs, are used to control BLDC and PMSM motors. These software algorithms improve efficiency and reduce operating costs by monitoring and controlling motor operation. Some of the main functions of the algorithm are motor initialization, Hall sensor rotor position detection, and switch signal checking for increasing or decreasing current reference.

6. How does the controller process motor sensor information

The three-phase BLDC motor has six states. As shown in the figure below, a three digit code can be used to represent the operation code number between 1 and 6. Place sensors to provide three digit data output using six out of eight opcodes (1 to 6). This information is useful as the controller can determine when an illegal opcode was issued and take action based on the legal opcodes (1 to 6). As shown below, the algorithm obtains the Hall sensor operation code and decodes it. When the value of the Hall sensor operation code changes, the controller changes the power on scheme to achieve commutation. The microcontroller uses opcodes to extract power on information from the lookup table. After the three-phase inverter is powered on with a new sector command, the magnetic field moves to a new position, pushing the rotor to move accordingly.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |