How Innovation in Motor Drivers Helps Meet the Challenge of Robot Motion Design

Time:2023-12-14

Views:467

From assisted surgery to lifting thousands of kilograms of heavy objects in manufacturing factories, robots have provided convenience in many aspects of our lives. The impact of robots on the modern world is obvious, but have you ever thought about how robot systems can achieve such precise, fast, and powerful movements? If the answer is through the motor, congratulations on your correct answer!

Robots often mimic operations that should have been performed by humans; In view of this, its function mainly includes adjusting position and direction through some form of displacement or rotation, which are generally achieved through electric motors.

Traditional robot application scenarios mainly focus on mechanical driving (such as arm manipulation or conveyor belt loops), while modern application scenarios are much simpler, such as camera rotation or precise mechanical beam turning to LiDAR sensors. You may be surprised to find that the basic applications of motors are the most basic fans and pumps, but in reality, they play an important role in heat dissipation and hydraulics.

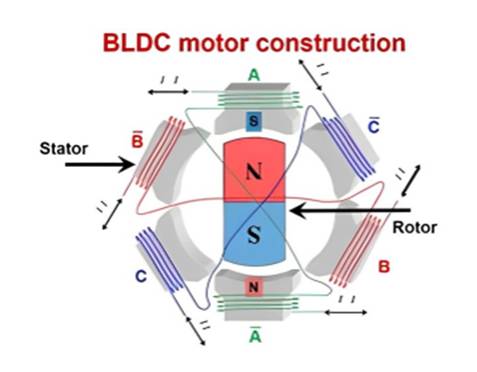

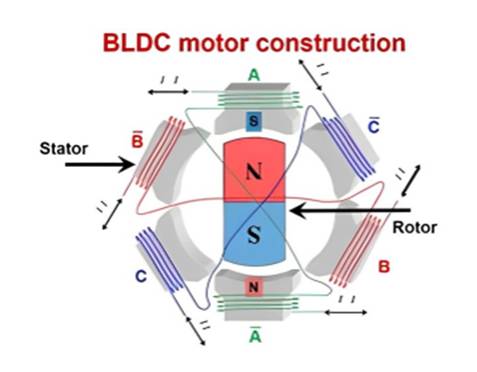

For example, a brushless direct current (BLDC) motor in a robotic arm joint (as shown in Figure 1) typically includes a rotating rotor and a stationary stator. Applying electrical signals to energize the coil windings on the stator can create a magnetic field, which generates magnetic force and causes the rotor to move, thereby rotating the joints inside the robotic arm. By using electronic signals reasonably, the robotic arm can not only move, but also move at specific speeds, positional accuracy, and torque.

Figure 1: Cross sectional view of BLDC motor structure

How motors drive the next generation of robots

In addition to precise and powerful tasks involving motion, advances in motor control semiconductors such as microcontrollers (MCUs) and integrated motor drivers are optimizing the motion of robots, but achieving this goal faces four major challenges.

Challenge 1: Continuously increasing security requirements for human-machine collaboration

In the past, for safety reasons, humans and robots needed to be strictly separated, usually by placing robots in cages. The improvement of automation requires closer human-machine collaboration and interaction. Collaborative robots can help improve work efficiency, but require motors that can ensure safe stopping, safe speed, torque, and motion control.

Devices such as C2000 32-bit TMS320F28P650DK MCU play a crucial role in helping to meet security requirements. The functional safety of these devices has been certified and can be integrated with safety peripherals for diagnosis, thereby simplifying designs that comply with the International Organization for Standardization (ISO) 10218 standard. At the analog end of the spectrum, intelligent gate drivers such as DRV8353F can help engineers achieve their safety goals through technical reports certified by T Ü V S Ü D. This supporting document can guide engineers to complete the design steps required to achieve safe torque closure according to the IEC 61800-5-2 standard. Both MCU and gate drivers can simplify the design process and achieve functional safety in motor systems with the help of certain components.

Challenge 2: Reduce weight, simplify wiring, and lower costs through a decentralized motor architecture

Motor electronic devices are transitioning from using control cabinets to being directly integrated into robot joints, which helps reduce weight, simplify wiring, and lower system costs. This trend has prompted component manufacturers to focus on developing solutions that can integrate more functions within smaller integrated circuit packages. Space limitations also require higher power density and power efficiency.

Gallium nitride field-effect transistors (such as LMG3422R050) integrate gate drivers, which can increase power stage efficiency to over 99%, thereby reducing or eliminating the need for heat sinks in integrated motors. With the help of real-time communication peripherals and absolute encoder interfaces, systems using MCUs such as TMS320F28065 can generate pulse width modulation signals with a resolution of picoseconds. These features reduce the wiring from more than 10 cables per motor to a total of two buses for the entire robotic arm. In this configuration, MCU and GaN field-effect transistors are used, allowing designers to optimize wired connections by adding single pair Ethernet functionality through Ethernet physical layer transceivers (such as DP83TG721).

Challenge 3: Achieving automation of precise motion tasks requires higher precision and accuracy

The miniaturization of products has had a certain impact on the selection of motors for many applications (servo, stepper, or brushless DC motors), and the complexity of motor control and position feedback has increased to achieve precise motion interaction with these small products. Semiconductor innovation makes it possible to achieve higher precision required for product miniaturization. For example, current sensors such as AMC3306 have a ± 50 µ V offset voltage and an integrated power supply. Integrating these features into one package can improve the accuracy of the control circuit and reduce the overall size of the printed circuit board.

Challenge 4: Optimize power efficiency and achieve mobile applications powered by batteries

Robots are not just fixed in one place, their applications are moving towards automation, helping to deliver packages and safely explore terrain. The current and future use of semiconductors for sensing, processing, and real-time control applications requires a balance between high performance and power efficiency to ensure reasonable battery life and possible range of travel.

Achieving high power efficiency is not necessarily very complex, nor does it require the use of complex design methods with multiple discrete components. For example, single motor controllers like MCT8316A can effectively operate small pump and fan motors by reducing the number of power consuming components in the robot. This highly integrated device includes six metal oxide semiconductor field-effect transistors, which can form a half bridge power stage for conveying motor current, as well as a digital core that can achieve simple trapezoidal motor control without coding.

What are the future development prospects of motor control?

The robots of the future will be beyond imagination, capable of easily completing tasks that seem impossible today - frequently working in the deepest trenches of the ocean or adventuring in unknown space. The new design may adopt increasingly advanced sensors, as we currently see with LiDAR and ultrasonic technology. From wired robots in the past to more software oriented solutions now, the way we communicate with robots may even change. The enhanced accessibility enables more reliable control of robots through speech, visual expression, and even just thinking. In this evolutionary process, with the continuous development of robot technology and applications, the motors required to drive its motion are bound to continue to evolve.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |