The stepping motor relies entirely on it for its undulating microsteps

Time:2023-11-21

Views:600

Do you know ‘Lingbo Micro Step‘? It is an exquisite and unparalleled lightness skill in martial arts novels, and the prerequisite for cultivating this lightness skill is to have deep internal power. Practicing martial arts is like this, and so is electronic semiconductors. Only by accumulating a lot of experience and technological precipitation can we make a durable product.

Toshiba has made great efforts in the field of motor drive, innovating the stepper motor drive chip and adding advanced dynamic hybrid attenuation (ADMD) technology, giving the stepper motor the ability to "flip and micro step". It is TB67S109AFTG! Another advantage of this chip is its small size, high efficiency, and many additional functions, providing more flexible choices for engineers to choose and apply motor drives in the future.

01 Electrical characteristic analysis

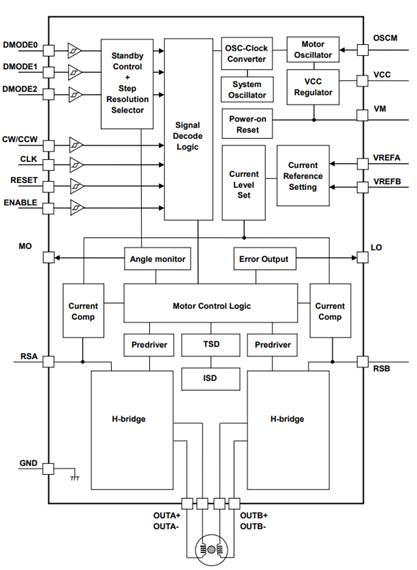

The Toshiba TB67S109AFTG is a 2-phase bipolar stepper motor driver equipped with a PWM chopper. It has a built-in clock decoder and is manufactured using the BiCD process, which can provide high current capacity. Its rated value under working conditions is 50V/4A; At the same time, TB67S109AFTG has high-precision driving capability, with a maximum of 32 subdivisions, and adopts Toshiba Advanced Dynamic Hybrid Attenuation (ADMD) technology, which can adapt to high-speed motor driving needs. In addition, the 5V voltage regulator integrated inside TB67S109AFTG can meet the requirements of single power supply.

The specific parameters are as follows:

•BiCD process integrated single chip IC.

•Equipped with built-in clock decoder.

•Capable of controlling 1 bipolar stepper motor.

•Constant current drive controlled by PWM.

•Allow full step, half step, 1/4, 1/8, 1/16, 1/32 step operation.

•Low conduction resistance (high side+low side=0.49 Ω (typical value)) MOSFET output stage.

•Adopting Advanced Dynamic Mixed Attenuation (ADMD) technology.

•It has a stable output of 50V high voltage and 4A high current.

•Error detection (TSD/ISD) signal output function.

•Built in error detection circuits (thermal shutdown (TSD), overcurrent shutdown (ISD), and power on reset (POR)).

•Built in VCC regulator for internal circuit use.

•The chopping frequency of the motor can be customized through external resistors and capacitors.

•Multiple packaging product lines:

TB67S109AFTG: P-WQFN48-0707-0.50-003;

TB67S109AFNG: HTSSOP48-P-300-0.50.

Note: Please pay attention to the heat dissipation conditions during use.

02 Functional Characteristic Analysis

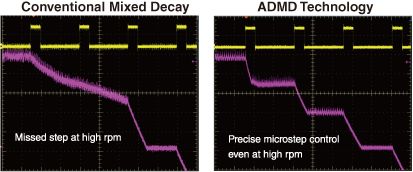

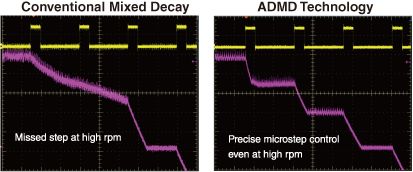

Adopting advanced dynamic mixed attenuation (ADMD) technology, dynamically adjusting the mixed attenuation ratio and optimizing the high-speed current drive of the stepper motor. As shown in the figure below, in the high-speed current driving state, traditional methods may experience out of step phenomenon (on the left of the figure), while ADMD can achieve precise control (on the right of the figure). Adopting ADMD technology can achieve tighter input current tracking, further enhancing efficient motor control under high speed conditions.

Manufacturing using the BiCD process helps to reduce the internal power consumption of the circuit. Driving MOSFETs with low conduction resistance (typical value of 0.49 Ω for high and low edges) can effectively reduce the heating of the driving IC. At the same time, using QFN48 packaging can also reduce the PCB area of the driving circuit and reduce production costs.

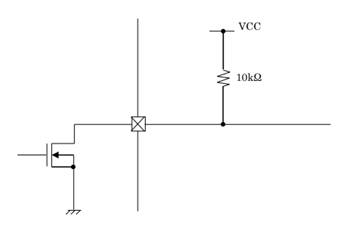

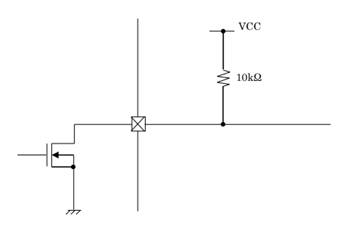

Error detection identification output function: TB67S109AFTG has an error detection function. When the driver chip detects the occurrence of thermal shutdown (TSD) or overcurrent (ISD), it will trigger the error detection identification output function, outputting low-level signals from the LO pin to peripheral modules, achieving fast fault handling operations.

03 Application Scenario

TB67S109AFTG is widely used in office automation equipment, commercial and industrial equipment, including robots and printers, due to its excellent driving performance and technology.

Toshiba Semiconductor has extensive research and development experience in motor driven ICs. Through continuous accumulation and sedimentation of technology, it has continuously "honed" in motor driven ICs, allowing the performance of motor driven ICs to be "stunning". In the future selection and reference of motor drive products, Toshiba will continue to provide you with more services and products

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |