What are the latest trends and innovations in brushless DC motor control technology and applications

Time:2023-11-04

Views:656

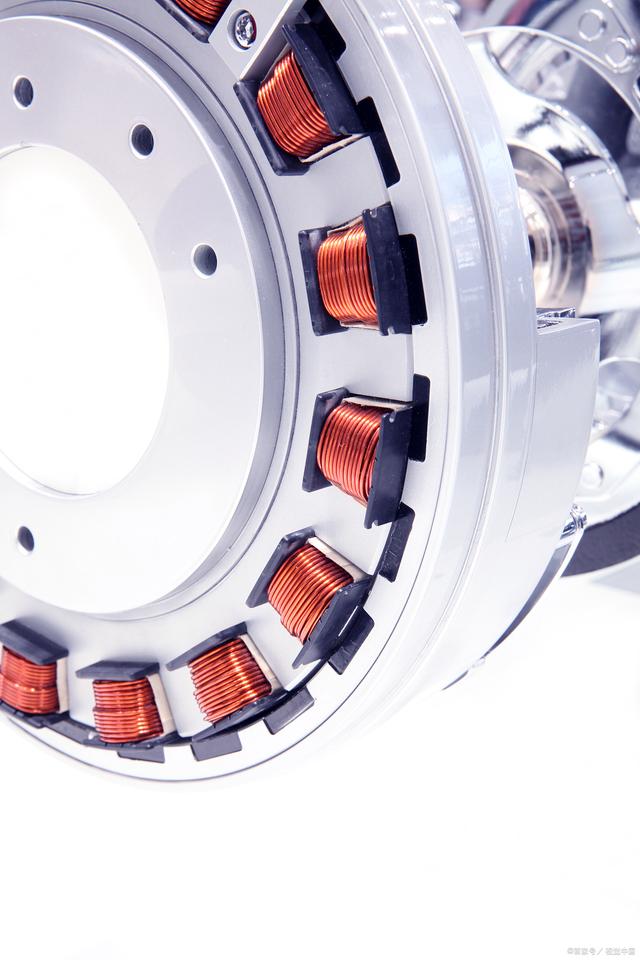

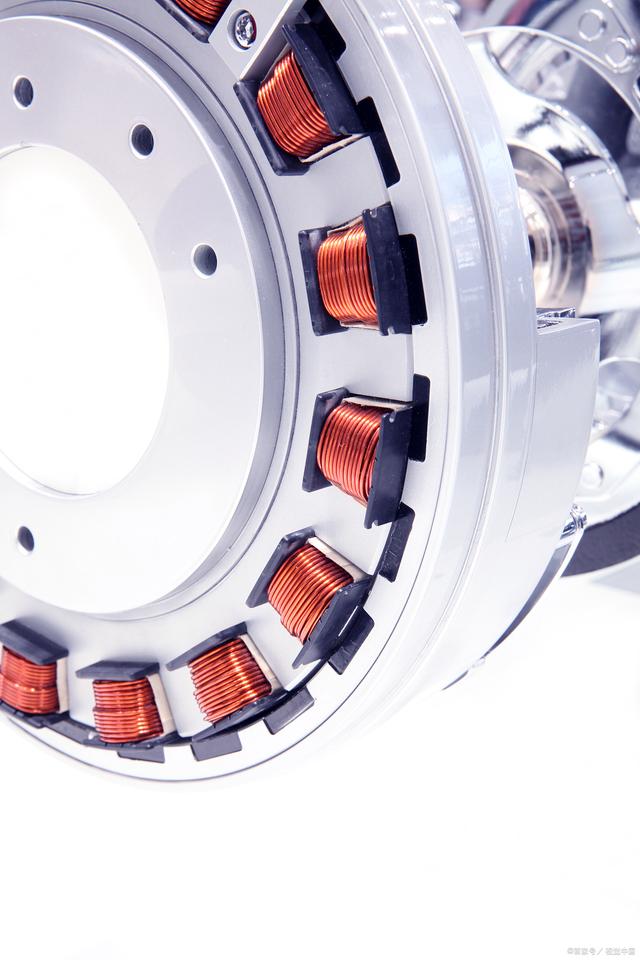

Brushless DC (BLDC) motors are widely used in various applications, such as electric vehicles, drones, robots, and industrial automation, due to their high efficiency, low maintenance, and precise control. However, brushless DC motor control also brings some challenges, such as complex commutation, torque ripple, sensorless operation, and noise reduction.

Magnetic Field Oriented Control and Space Vector Modulation

Magnetic Field Oriented Control and Space Vector Modulation

Field Oriented Control (FOC) is a technology that allows you to independently control the torque and speed of brushless DC motors by aligning the stator magnetic field with the rotor magnetic field. Magnetic field oriented control requires a feedback mechanism, such as a position sensor or back electromotive force estimation, to determine the rotor angle and adjust the current accordingly. Field oriented control can reduce torque ripple, improve efficiency, and expand the speed range of brushless DC motors. Space Vector Modulation (SVM) is a method of generating the optimal voltage vector for brushless DC motors by switching the three-phase inverters in a specific order. Space vector modulation can reduce the switching losses, harmonics, and noise of brushless DC motors, and improve the output voltage and power.

Sensorless control

Sensorless control is a technology that eliminates the need for position sensors in brushless DC motors by estimating rotor position using back electromotive force or motor terminal voltage and current. Sensorless control can reduce the cost, complexity, and size of brushless DC motors, and improve their robustness and reliability. However, sensorless control also has some drawbacks, such as low speed operation, startup issues, and parameter changes. Therefore, sensorless control requires advanced algorithms such as sliding mode observers, Kalman filters, or artificial neural networks to overcome these challenges and achieve precise and stable control.

digital control

Digital control is a technology that uses microcontrollers, digital signal processors, or field programmable gate arrays to implement brushless DC motor control algorithms (such as FOC, SVM, or sensorless control). Digital control can provide many advantages, such as flexibility, programmability, scalability, and integration. Digital control can also achieve more functions, such as fault detection, protection, communication, and diagnosis. However, digital control also requires careful design and optimization, such as sampling frequency, resolution, delay, and immunity, to ensure the performance and quality of brushless DC motor control.

Wireless control

Wireless control is a technology that allows you to remotely communicate and control brushless DC motors using wireless devices such as smartphones, tablets, or laptops. Wireless control can provide convenience, mobility, and accessibility for brushless DC motor applications, especially in harsh or dangerous environments. Wireless control can also achieve data collection, analysis, and visualization, which can help monitor and optimize the performance and efficiency of brushless DC motors. However, wireless control also brings some challenges, such as security, reliability, and compatibility, which require appropriate encryption, authentication, and protocol design.

intelligent control

Intelligent control is a technology that utilizes artificial intelligence, machine learning, or deep learning to enhance the self-learning, adaptive, and self optimization control capabilities of brushless motors. Intelligent control can help overcome the limitations and uncertainties of traditional control methods, such as parameter changes, nonlinearity, disturbances, and faults. Intelligent control can also achieve more functions, such as prediction, classification, and recognition, thereby improving the safety and intelligence of brushless DC motor applications. However, intelligent control also requires high computing power, large datasets, and complex algorithms, which will increase the cost and complexity of brushless DC motor control systems.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |