Utilizing Packaging, IC, and GaN Technology to Improve Motor Drive Performance

Time:2023-10-15

Views:617

Author: Nenad Belancic, Adam Gozdzicki

The technological advancements in motor drive design have opened many doors for us. For example, in motion control systems, higher accuracy, efficiency, and control capabilities bring many benefits to user experience and security, resource optimization, and environmental friendliness. The introduction of brushless motor technology is an important step in the industry towards comprehensively improving efficiency.

The transition from brushing to brushless has been going on for a long time, and with the introduction of more new technologies and system components, it is still moving forward. At the same time, the latest developments in electrical components have also made better thermal management, higher power density, and miniaturization possible, enabling more complex tasks to be performed at a more competitive cost.

Industry leading semiconductor technology can make low and medium voltage motor designs more efficient and compact, and provide stronger functionality for end users. Engineers can choose different semiconductor solutions to further optimize motor drive design.

The technical parameters such as switching frequency and thermal resistance of the terminal product have put forward certain requirements for the driver. In order to create an optimal design that can increase power density and reduce size, designers must minimize losses, including conduction losses and switching losses, and improve thermal management performance.

Improvement of high-power packaging technology

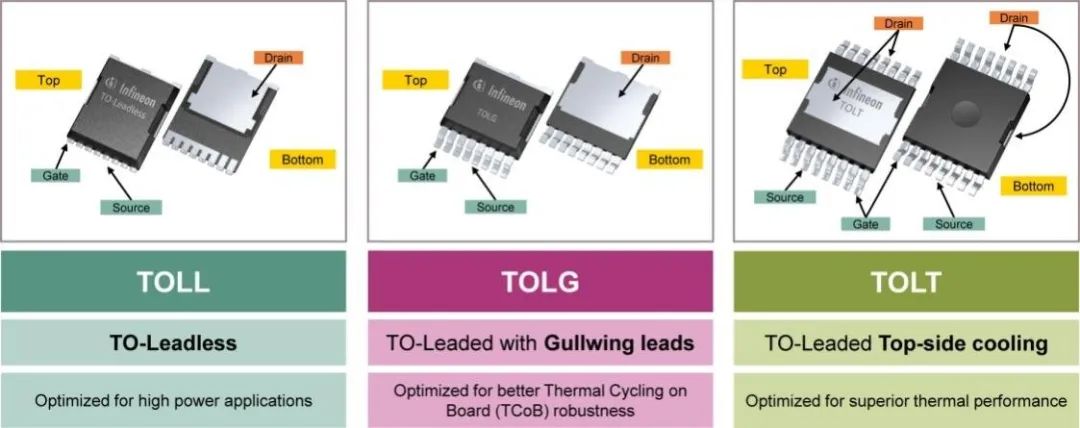

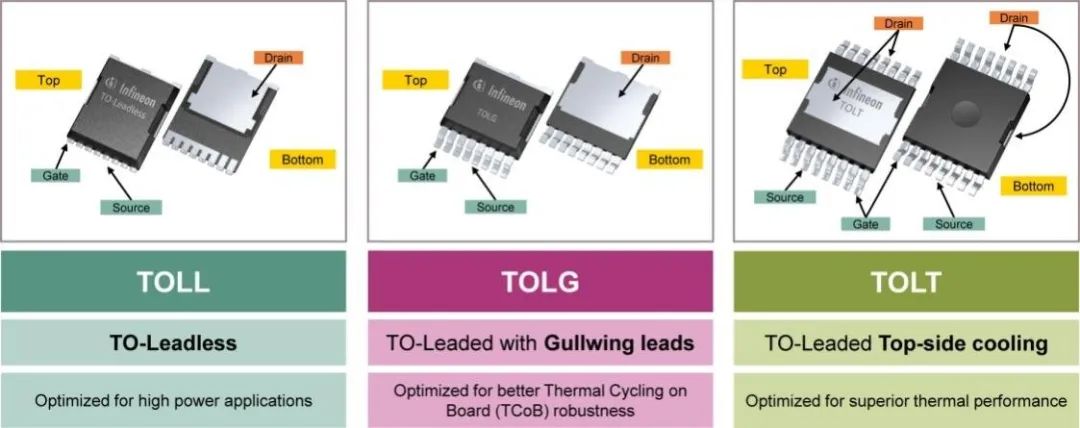

With the trend of increasing battery voltage in robots and electric tools, the power of motor drivers is also constantly increasing. This means that there is an increasing demand for power semiconductors in terms of high rated current, durability, and extended lifespan. A far-reaching scenario to meet these requirements is the new packaging technology platform, which has three different variations, and its selection depends on specific requirements (see Figure 1).

Figure 1: Comprehensive comparison of TOLL, TOLG, and TOLT packaging technologies. Source: Infineon

The optimized TO pin free (TOLL) can handle currents up to 300A, significantly reducing the footprint and increasing power density. Compared to D2PAK, the footprint has been reduced by 30% and the height has been reduced by 50%, resulting in an overall 60% space savings and a more compact design.

The TO with gull wings comes in a pin based (TOLG) package, providing a compatible overall size with the TO without pin packaging. The additional advantage of the gull wing pin compared to the non pin type is that it improves the on board thermal cycling (TCOB) performance by two times. The performance of this packaging on insulated aluminum metal substrates (Al IMS) is excellent.

TOLT is a type of packaging in the TOLx series that uses TO with pin tip cooling. By cooling at the top, the drain is exposed to the packaging surface, allowing 95% of the heat to be directly dissipated onto the heat sink. Compared with TOLL packaging, RthJA is increased by 20% and RthJC is increased by 50%.

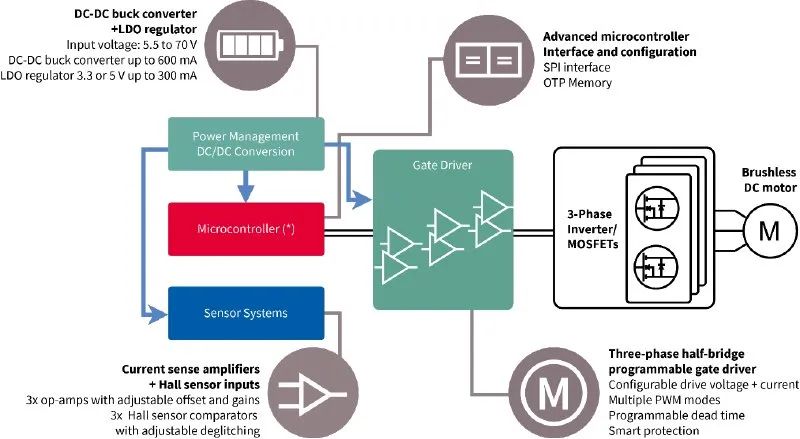

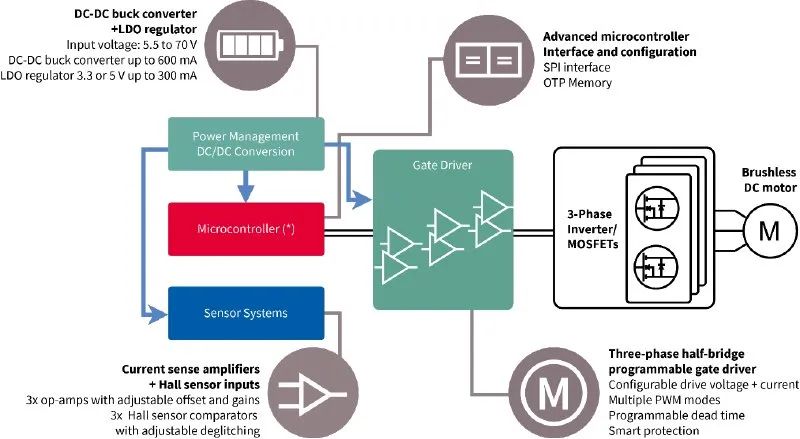

Three phase gate drive controller chip

The new three-phase intelligent motor driver chip can be used to develop high-performance motor drivers using brushless direct current (BLDC) or permanent magnet synchronous (PMS) motors. These designs are particularly suitable for mobile robots, drones, and electric tool applications.

Figure 2: The gate drive controller chip can be integrated with the microcontroller in the same package. Source: Infineon

With over 50 programmable parameters using built-in digital SPI interfaces, the motor driver chip can be highly configurable to drive a wide range of MOSFETs, achieving optimal system efficiency. Other advantages include:

·Reduce the number of external components and PCB area

·Better efficiency and electromagnetic interference (EMI) performance

·Maximum flexibility in using different inverter FETs

·With high-precision current detection capability, while saving the number of external components

·Higher dynamic range can further improve signal resolution

·Higher reliability and fault detection capabilities

·Utilizing gallium nitride to improve efficiency and power density

In some cases, an important design goal is to integrate power electronic devices near the motor or within the same housing. The potential benefits of this design include increasing power density and reducing BoM costs, as the motor and electronic components can be placed in a smaller shell, saving costs through improved system efficiency.

Usually, heat dissipation and large capacitance have been unfavorable factors affecting the performance of integrated motor drives (IMDs). The design based on gallium nitride (GaN) provides conditions for overcoming the difficult trade-off between switching speed and maximum output power. By utilizing Field Oriented Control (FOC), higher switching frequencies have been achieved, which brings many system advantages, including reducing large capacitor capacity, reducing motor ripple current, reducing torque ripple, and acoustic noise. In addition, higher frequencies can also lower the motor temperature. This combination can achieve higher end-to-end system efficiency improvements.

In drones, the benefits of improving system efficiency are not only due to reduced losses, which can lead to higher design efficiency, but also smaller size, which is a key factor in making drones lighter and flying farther.

Looking Forward to the Future

Higher product integration can help engineers more easily implement buy and use solutions, thereby shortening product time to market. Just like motor drive chips, combining high integration with a wide range of programmable functions can create competitive advantages and system flexibility. The new packaging and broadband gap technology can also provide additional advantages for motor control systems, such as:

The new packaging design can provide more optimized thermal management performance, as the heating of power switches is always closely related to switch losses.

The new broadband gap devices have laid the foundation for driving higher switching frequencies, which is greatly beneficial in improving accuracy and reducing the occupied area.

In order to develop the most competitive motor control system, designers must fully utilize all the latest available technologies.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |