Three Methods to Suppress or Reduce Ripples in Switching Power Supplies

Time:2023-06-13

Views:952

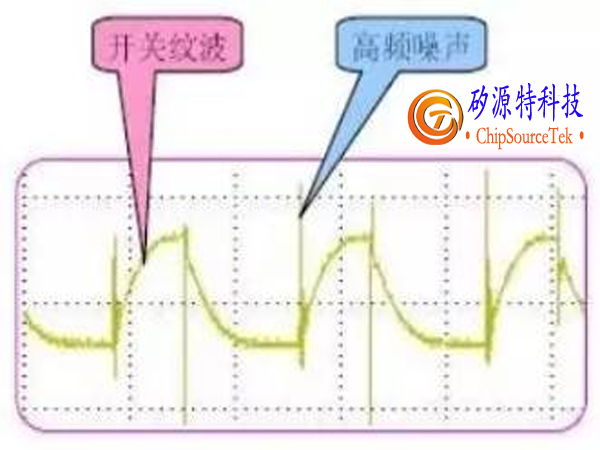

Our ultimate goal is to reduce the output ripple to a tolerable level. The fundamental solution to achieving this goal is to avoid the generation of ripple as much as possible. Firstly, we need to understand the types and causes of switching power supply ripple.

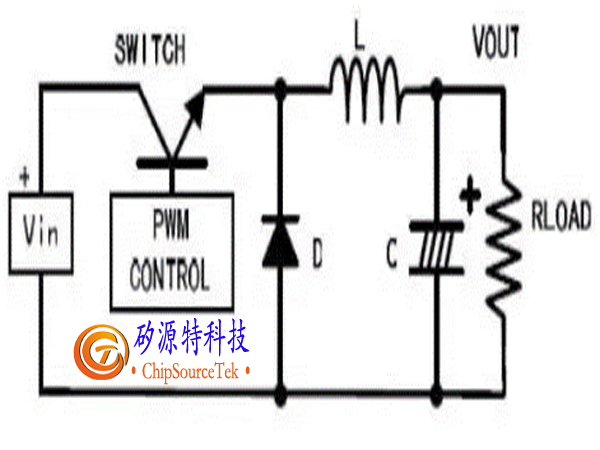

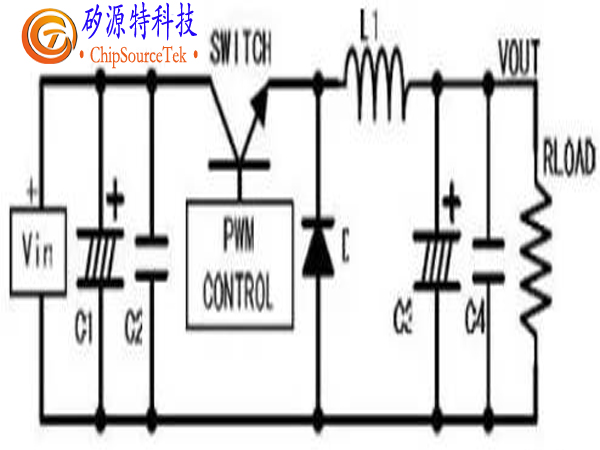

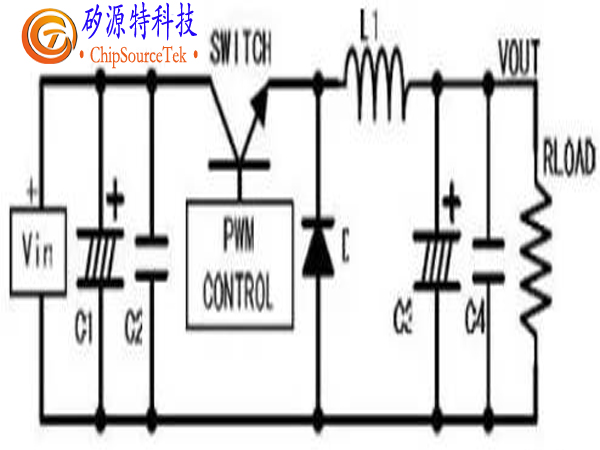

The above figure shows a simple topology structure of a buck buck buck power supply in a switching power supply.

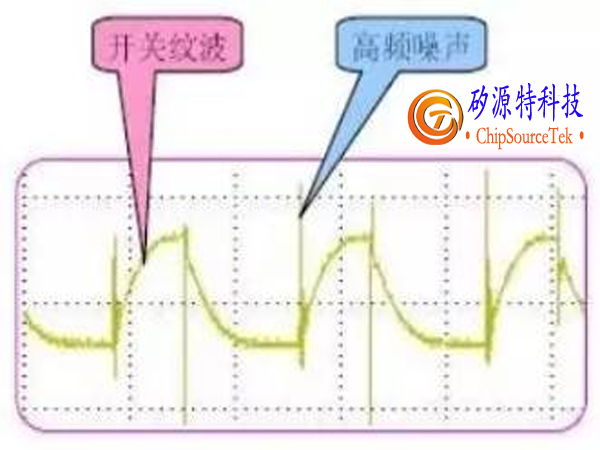

With the switch of SWITCH, the current in inductor L also fluctuates up and down at the effective value of the output current. So there will also be a ripple with the same frequency as SWITCH at the output end, which is generally referred to as the ripple. It is related to the capacity of the output capacitor and ESR. The frequency of this ripple is the same as that of a switching power supply, ranging from tens to hundreds of KHz.

In addition, the Bipolar junction transistor or MOSFET is generally selected as the switch. No matter which one is, there will be a rise time and a Fall time when it is turned on and off. At this time, a noise with the same frequency or odd frequency multiplication as the rise and Fall time time of SWITCH will appear in the circuit, which is usually tens of MHz. Similarly, at the moment of reverse recovery, the equivalent circuit of diode D is the series connection of resistor, capacitor, and inductor, which can cause resonance and generate noise

The frequency is also several tens of MHz. These two types of noise are generally called high-frequency noise, and their amplitude is usually much larger than the ripple.

If it is an AC/DC converter, in addition to the two types of ripple (noise) mentioned above, there is also AC noise. The frequency is the frequency of the input AC power supply, which is around 50-60Hz. There is also a common mode noise caused by the equivalent capacitance generated by the use of enclosures as heat sinks in many power devices of switching power supplies.

Measurement of ripple in switching power supply

Basic requirements:

Using oscilloscope AC coupling

20MHz Bandwidth throttling

Unplug the ground wire of the probe

1. AC coupling is the process of removing superimposed DC voltages to obtain accurate waveforms.

2. Turning on the 20MHz Bandwidth throttling is to prevent the interference of high-frequency noise and the detection of wrong results. Due to the large amplitude of high-frequency components, they should be removed during measurement.

3. Unplug the grounding clamp of the oscilloscope probe and use a grounding ring for measurement to reduce interference. Many departments do not have grounding rings, and if the error allows, the grounding clamp of the probe can be directly used for measurement. But this factor should be considered when determining whether it is qualified.

Another point is to use 50? Terminal. According to the information on the Yokogawa oscilloscope, 50? The module removes the DC component and measures the AC component. But few oscilloscopes are equipped with such specialized probes, and in most cases, the standard 100K is used? To 10M? The impact of the probe measurement is currently unclear.

The above are the basic precautions when measuring switch ripple. If the oscilloscope probe does not directly contact the output point, it should be twisted pair or 50? Measurement using coaxial cables.

When measuring high-frequency noise, use the full passband of an oscilloscope, usually in the range of hundreds of megabits to GHz. The others are the same as above. Different companies may have different testing methods. Ultimately, one must be clear about their own test results. Secondly, we need to gain customer recognition,

Regarding the oscilloscope:

Some digital oscilloscopes cannot accurately measure ripple due to interference and storage depth. At this point, the oscilloscope should be replaced. Sometimes, although the bandwidth of old analog oscilloscopes is only a few tens of megabytes, their performance is better than that of digital oscilloscopes.

Suppression of Switching Power Supply Ripples

For switch ripple, there must be both theoretical and practical existence. There are usually three ways to suppress or reduce it:

1. Increase inductance and output capacitor filtering

According to the formula of switching power supply, the fluctuation of current inside the inductor is inversely proportional to the inductance value, and the output ripple is inversely proportional to the output capacitance value. So increasing the inductance value and output capacitance value can reduce ripple.

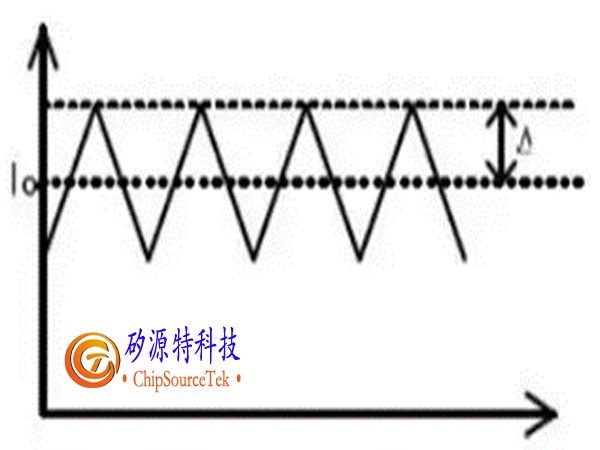

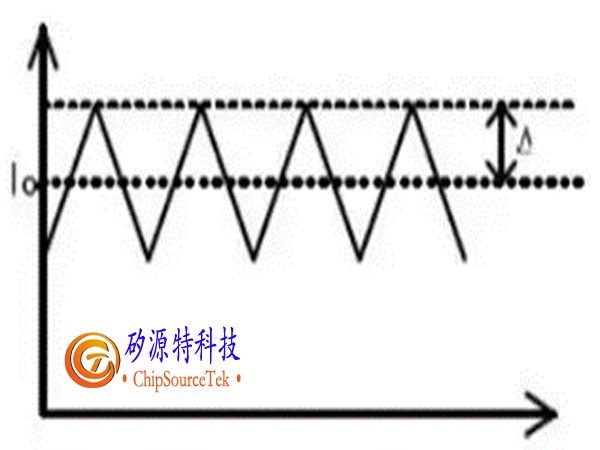

The above figure shows the current waveform within the inductance L of the switching power supply, and its ripple current △ I can be calculated by the following equation:

It can be seen that increasing the L value or increasing the switching frequency can reduce the current fluctuation within the inductor.

Similarly, the relationship between output ripple and output capacitance: vripple=Imax/(Co × f) . It can be seen that increasing the output capacitance value can reduce ripple.

Generally, aluminum Electrolytic capacitor is used for output capacitor to achieve the purpose of large capacity. However, the Electrolytic capacitor is not very effective in suppressing high-frequency noise, and the ESR is relatively large, so a Ceramic capacitor will be connected in parallel to it to make up for the shortage of aluminum Electrolytic capacitor.

At the same time, when the switching power supply is working, the input voltage Vin remains unchanged, but the current changes with the switch. At this point, the input power supply will not provide current well. Usually, a parallel capacitor is used to provide current near the current input terminal (in the case of BucK type, near SWITcH).

After applying this strategy, the BUCK type switching power supply is shown in the following figure:

The above approach has a limited effect on reducing ripple. Due to volume limitations, the inductance will not be too large; Increasing the output capacitance to a certain extent has no significant effect on reducing ripple; Increasing the switching frequency will also increase the switching loss. So when the requirements are relatively strict, this method is not very good.

For the principles of switching power supplies, you can refer to various design manuals for switching power supplies.

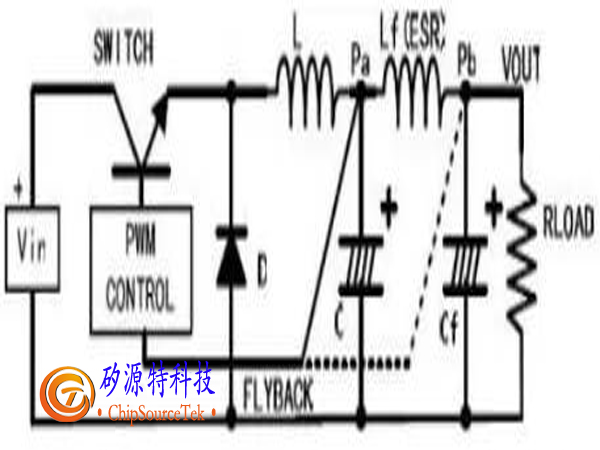

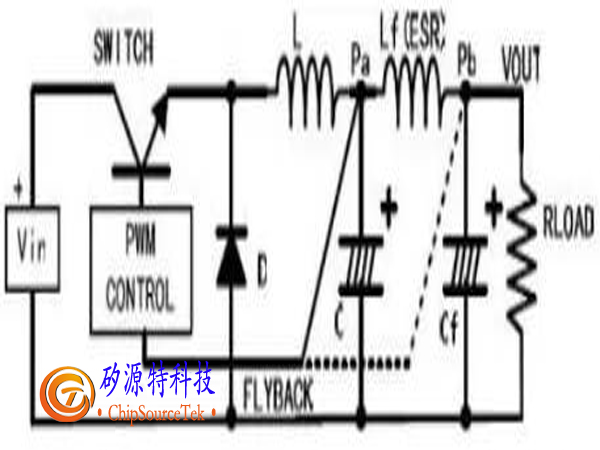

2. Secondary filtering, which means adding an LC filter

LC filters have a significant inhibitory effect on noise ripple. Choosing an appropriate inductance and capacitor to form a filtering circuit based on the frequency of the ripple to be removed can generally effectively reduce the ripple.

However, in this case, it is necessary to consider the sampling point for feedback comparison voltage. (As shown in the following figure).

If the sampling point is selected before the LC filter (Pa), the output voltage will decrease. Because any inductor has a DC resistor, when there is current output, there will be a voltage drop on the inductor, resulting in a decrease in the output voltage of the power supply. And this voltage drop varies with the output current.

The sampling point is selected after the LC filter (Pb), so that the output voltage is the voltage we want to obtain. However, introducing an inductor and a capacitor inside the power system may lead to system instability. There are many materials about system stability that have been introduced, but I won‘t go into detail here.

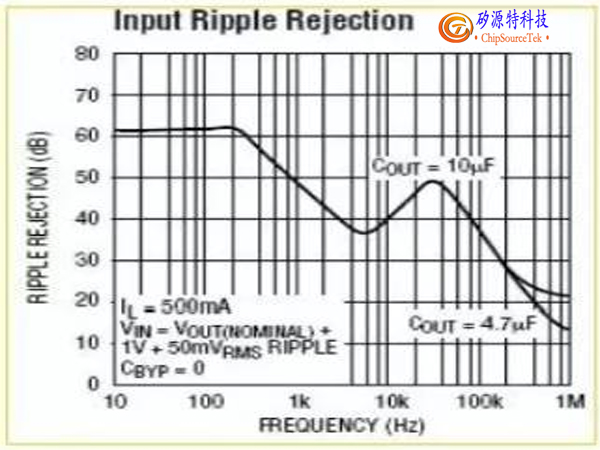

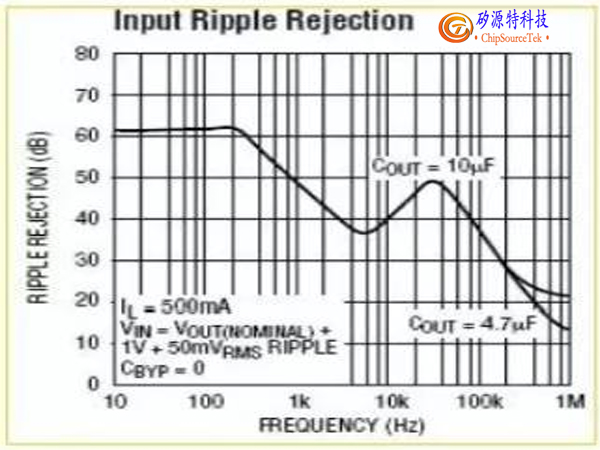

3. After switching power supply output, connect to LDO filtering

This is an effective way to reduce ripple and noise, with a constant output voltage and no need to change the original feedback system, but it is also a cost and power consumption method.

Any LDO has one indicator: noise suppression ratio. It is a frequency dB curve, as shown in the right figure, which is the curve of LT3024 from Lingte Company.

After LDO, the switching ripple is generally below 10mV.

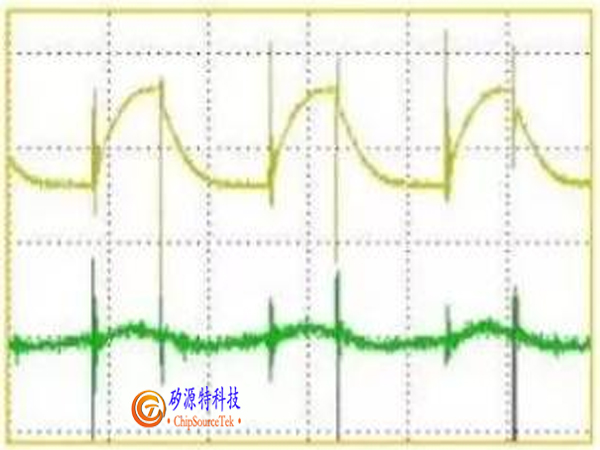

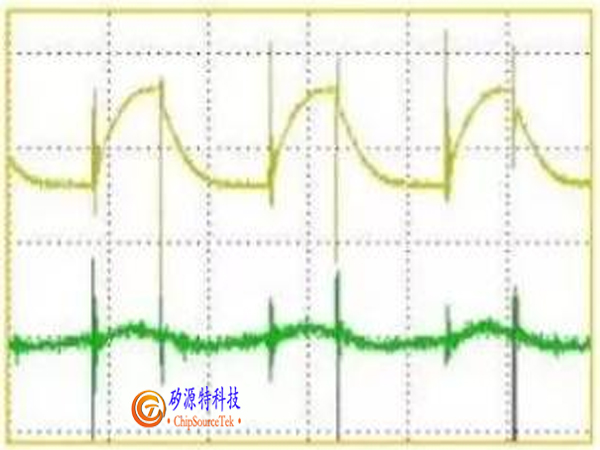

The following figure shows the comparison of ripples before and after LDO:

Comparing the curve in the above graph with the waveform in the left graph, it can be seen that LDO has a very good suppression effect on switching ripple of several hundred KHz. But in the high-frequency range, the effect of this LDO is not as ideal.

Reduce ripple. The PCB wiring of switching power supplies is also crucial, which is a very important issue. There are specialized switch power supply PCB engineers, and for a simple reference, please refer to the AN1229: SIMPLE SWITCHER PCB Layout Guidelines of National Semiconductor Corporation in the United States

For high-frequency noise, due to the high frequency and large amplitude, although the post filtering has a certain effect, the effect is not significant. There is specialized research in this area, and a simple approach is to connect capacitors C or RC on diodes, or to connect inductors in series.

4. Connect capacitor C or RC on the diode

The above diagram shows the equivalent circuit of the actual diode. When the diode conducts and cuts off at high speed, parasitic parameters should be considered. During diode reverse recovery, the equivalent inductance and equivalent capacitance become a RC oscillator, generating high-frequency oscillation. To suppress this high-frequency oscillation, a capacitor C or RC buffer network needs to be connected in parallel at both ends of the diode. The resistance is generally taken as 10 Ω -100 Ω, and the capacitance is taken as 4.7pF-2.2nF.

The value of the capacitor C or RC in parallel on the diode needs to be determined through repeated tests. If selected improperly, it can actually cause more severe oscillations.

If there are strict requirements for high-frequency noise, soft switching technology can be used. There are many books dedicated to introducing soft switches.

5. Diode followed by inductance (EMI filtering)

This is also a commonly used method for suppressing high-frequency noise. Choosing appropriate inductance components for the frequency of noise generation can also effectively suppress noise. It should be noted that the rated current of the inductor should meet the actual requirements. A relatively simple approach, without further explanation.

Summary

The above is a summary of the switching power supply ripple. It would be even better if some waveforms could be added. Although it may not be complete, it is sufficient for general applications. Regarding noise suppression, it is not necessarily entirely applicable in practice. It is important to choose appropriate methods based on one‘s own design requirements, such as product volume, cost, development cycle, etc.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |