Low cost brushless DC motor control MCU

Time:2023-04-13

Views:1101

The contribution rate of motors to energy consumption is close to 50% in the United States, so reducing motor energy consumption can effectively improve energy utilization. Using advanced microcontroller (MCU) technology to achieve motor control is an effective method. This article introduces the development and application of motor control MCU technology.

One of the main targets for reducing energy consumption is electric motors, which consume approximately 50% of the total energy consumption in the United States. More than 50 motors can be found anywhere in the family, typically between 70 and 80. In the industrial field, factory automation also extensively utilizes motors.

Today, recent developments in MCU technology allow motors to operate more efficiently at lower costs. In some markets, this can accelerate the transition from electromechanical to electronic control, enabling variable speed motor control to optimize motor efficiency and reduce the cost of all applications at the device level.

Low cost brushless DC motor control MCU

Compared with the commonly used brushless motors in motor control, the Brushless Direct Current (BLDC) motor controlled by MCU eliminates brush wear and arc mechanism, so the lifespan of the motor is essentially limited to the lifespan of the bearings. In addition, the advantages of the BLDC motor system based on MCU include high efficiency, high torque inertia ratio, higher speed performance, low noise, better thermal efficiency, and low EMI characteristics.

The use of 8-bit MCUs specifically designed for mass production of motor control is a very low-cost method to solve digital motor control problems. Due to its performance of up to 10 MIPS and dedicated hardware for motion control, including a 14 bit PWM for center alignment, a motion feedback module, and a high-speed ADC, applications that previously required expensive processors can now be solved using low-cost 8-bit MCUs.

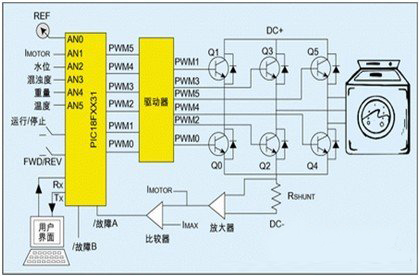

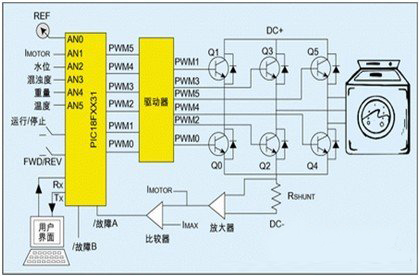

Figure 1: Application example of MCU in washing machines

An 8-bit microcontroller drives a three-phase ACIM variable frequency drive.

The three-phase PWM control in some MCU, such as PIC18F4431, can provide all three controls of a BLDC using hardware, minimizing the software that must be developed and debugged. Up to 8 available PWM channels, usually only 6 are needed to drive three-phase motors. Therefore, the remaining two channels can be used for other functions without the need for additional devices. The motion feedback module with integral encoder interface, which is the main part of MCU, reduces the number of devices and system costs.

The MCU with an ADC with a sampling rate of 200K per second can provide the necessary speed for closed-loop control. The simultaneous use of two different channels makes it possible to simultaneously sample voltage and current. When measuring the back end electromotive force (EMF) in closed-loop motor control, such fast switching is required, and the ability to synchronize ADC with PWM on the rising or falling edge reduces switching noise. In summary, these modules eliminate the need for external motor control devices such as high-speed ADC and position encoder.

In many motor control applications, fail safe operation is very important. The MCU with a fail safe clock monitor (an internal RC oscillator that can be used as a backup clock in the event of a crystal oscillator failure) enables design engineers to provide highly reliable digital control. The programmable dead time delay on PWM reduces switching noise, reduces development time by several weeks, and meets critical program deadlines to enable new products to be launched. In all cases, MCU with reliable flash memory provides the possibility of rapid market launch and flexibility to adjust according to changes in requirements before installation or during use.

Market driving factors and solutions

The requirements for electronic motor control in household electronic devices, as well as the industrial and automotive markets, have promoted the demand for MCUs with advanced motor control peripherals.

In the home appliance market, motor control with improved performance is required to meet government planning standards, such as the Energy Star Program of the U.S. Environmental Protection Agency, which promotes manufacturers to launch high-performance home appliances. Washing machines are an important field of high-performance motor control. The direct drive washing machine eliminates the transmission belt between the motor shaft and the washing machine agitator, allowing for different speeds and agitator modes.

A manufacturer‘s completely redesigned washing machine reduces electricity consumption by 38% and water consumption by 17% compared to traditional washing machines. The motor control MCU adjusts the power of the motor based on the amount and type of laundry. However, home appliance users are still sensitive to the initial purchase price, so manufacturers must continuously reduce their development and production costs to make more advanced appliances acceptable to more consumers.

In home appliances, the 8-bit MCU designed specifically for low-cost motor control applications integrates functions that minimize additional devices. Under the conditions of motor PWM, fault safe clock monitor, and highly reliable flash memory on the circuit board, the MCU simplifies the design of home appliance motor control and can achieve low-cost goals.

In industrial applications, the cost of electricity and the downtime of assembly operations can reduce the profits of manufacturers. An industrial example of how the control of motor performance improvement directly affects efficiency and revenue is to replace the valve in an industrial water pump with a variable speed (VSD) system based on MCU.

For the pump or fan, the power consumption is proportional to the cube root of the shaft speed. When the shaft speed decreases by 10%, the flow decreases by 10%, and the power consumption decreases by 27%. If the speed is reduced by 20%, the power consumption will be reduced by 49%. By using MCU variable speed motor control instead of constant speed motor valves to reduce flow, it has been proven that energy savings of 25-40% can be achieved for centrifugal pumps, fans, and hair dryers in industrial applications.

The benefits of industrial applications are evident, as the use of MCU driven variable speed motor control relies on other factors such as flexibility and reliability - these factors can avoid downtime caused by faults or maintenance. MCU with flash memory and EEPROM provides the flexibility to meet industrial user requirements through reprogrammable features when upgrades or control program changes are required. The MCU with 16KB flash memory and 256B EEPROM provides sufficient memory in an 8-bit MCU to handle many changes that may be required in industrial environments. Equally important, Microchip‘s flash memory adopts PMOS electronic erasable unit processing technology, which generally has a data storage unit capable of withstanding 1 million erase/write cycles, and data can maintain performance for over 40 years.

The existing automotive motor applications include using motors to open and close windows and doors, as well as positioning the vehicle seat. Due to their low frequency of use, these applications are not sensitive to low efficiency, but high utilization applications, such as passenger temperature environmental control and engine box fans, continuously consume limited electrical energy from cars. The motor controlled MCU allows the environmental control fan to operate at a speed that maintains a comfortable temperature, reducing noise and power consumption.

In many cases, the motor control MCU must use a Control Area Network (CAN) or Local Interconnection Network (LAN) to connect to the car network. For body electronics, low-cost LIN protocols are now used to reduce overall system costs. In some MCU series, a USART module that supports LIN1.2 can be found, providing automatic wake-up and baud detection at the start bit.

As control algorithms become increasingly complex in all segmented markets, the performance of digital motor controllers has risen from MCU to DSP level. Digital Signal Controllers (DSC) bring higher performance and affordable, design engineer friendly MCU technology for more mature motor control designs, including those with vector control applications. DSC operates at a speed of up to 30MIPS, with up to 144KB of flash memory and integrated peripherals dedicated to motor control, enabling more advanced and new motor control applications. By using electronic motor control based on DSP and DSC, the home appliance industry and automobiles not only have higher work efficiency and provide more functions, but also have an acceptable price.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |