Recover energy in DC motor drive

Time:2023-02-27

Views:1231

When the motion mass in the permanent magnet motor driver is decelerated, the energy stored in the mechanical system can be returned to the power supply through the motor driver. If this energy is not properly considered, it may cause the power supply voltage to rise, thus damaging the motor driver or the rest of the system.

In this paper, we will study the method of safely dissipating this energy. To simplify the example, a DC brushless motor is shown. This also applies to brushless motor systems.

Conservation of energy

Conservation of energy is a basic principle of physics - energy can neither be created nor destroyed.

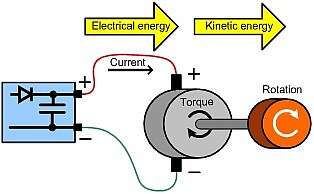

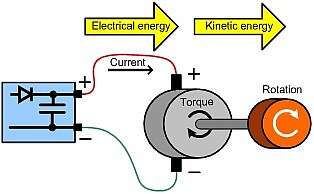

When something (such as a mass) moves or rotates, it will accumulate kinetic energy. In the motor system, the kinetic energy comes from the power supply that provides electric energy for the motor, and the motor generates torque to accelerate the mass.

Energy is stored in the inertia of the motor rotor and the mechanical system connected to the motor. For simplicity, consider the mechanical system as a flywheel coupled to the motor shaft (Figure 1).

Figure 1 Flywheel example of mechanical system

Kinetic energy can be expressed by I ω 2 Calculation, where I is the moment of inertia, ω Is angular velocity. The higher the speed or the greater the inertia, the more energy will be stored.

This is a very obvious concept - it requires energy to make something move. What is less obvious is what happens when you want to stop exercising. To stop or slow down the mass of motion, the stored kinetic energy must be transferred to a certain place. But where?

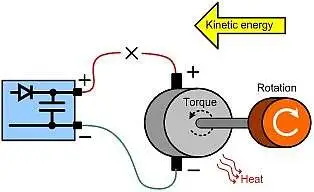

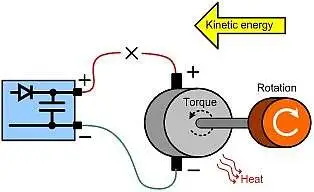

When you disconnect the power supply of the rotating motor, the energy stored in the motion mass will be dissipated into the mechanical loss of the system. Most of the energy is converted into heat due to friction (Figure 2). Unless there is great friction, the motor will slide and stop very slowly. The motor becomes a generator, but since there is no path for the current to flow, there is no electromagnetic torque to help stop the motor.

Figure 2 Friction in the stop motor

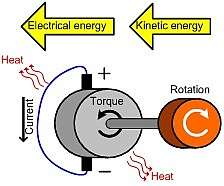

If the output of the short-circuit motor provides a path for the current to flow out of the generator, the current will produce a torque opposite to the direction of rotation (Figure 3). This will cause the motor to stop quickly. In this case, most of the energy is dissipated in the form of heat in the winding resistance of the motor and any resistance in the current path, thus making the motor short circuit.

Fig. 3 Torque is opposite to rotation

This is sometimes called "short braking". In fact, the short circuit is usually realized by opening the low side MOSFET of the H bridge to provide the current path.

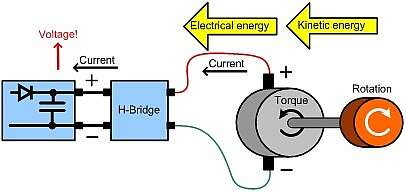

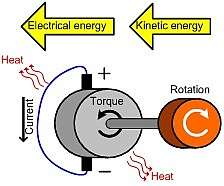

When the control system wants to reduce the motor speed quickly, the polarity of the current applied to the motor will be reversed to provide the torque opposite to the movement. After completion, the stored kinetic energy can be driven back to the power supply through the motor drive circuit.

If the power supply is a perfect battery, the energy will flow back to the battery and be recycled. However, in the real world, the power supply is usually DC power supply. Unless this power supply is specially designed, DC power supply can only provide current. Because it cannot absorb current, the place where energy must flow is into the capacitor as part of the power supply.

The energy stored in the capacitor can be calculated with CV2, where C is the capacitance and V is the voltage. As energy flows into the capacitor, the voltage at both ends of the capacitor must increase (Figure 4).

Fig. 4 Increasing capacitor voltage with the increase of energy

If the energy is small (either the speed is low or the inertia is small), the voltage increase may be small enough to cause no problems. However, in some cases, if there is too much energy or insufficient capacitance, the voltage may rise to a destructive level. This may damage the motor drive circuit or other circuits connected to the same power supply.

Dissipated energy

There are several ways to deal with the energy recovered from the power supply. One is to place a large number of capacitors on the power supply. In some cases, this may be all that is needed, but in most cases, large capacitors are not practical due to physical or cost constraints.

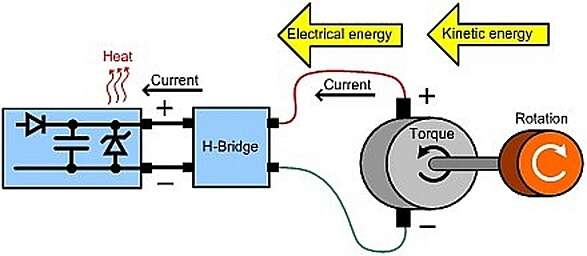

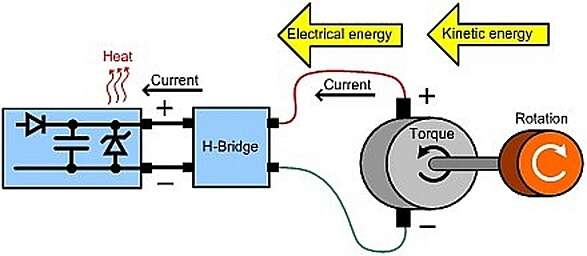

Another way to process energy is to use semiconductor clamping devices at both ends of the power supply, such as TVS or Zener diodes (Figure 5). The clamp is designed to fail when it is just above the normal operating voltage of the power supply. When the recovered energy causes the voltage to rise, the clamp will fail and protect the system. The energy returned to the power supply dissipates in the form of heat in the clamping device.

If the energy is moderate, the solution is simple and feasible.

Fig. 5 Semiconductor clamp for dissipating energy

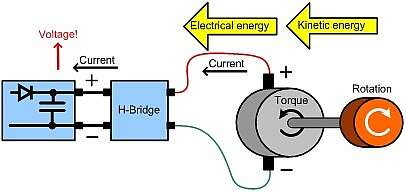

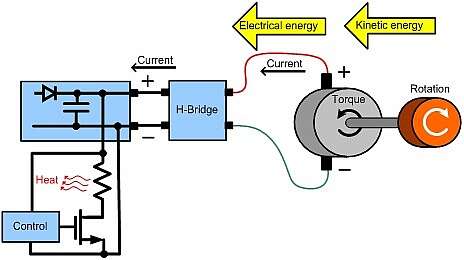

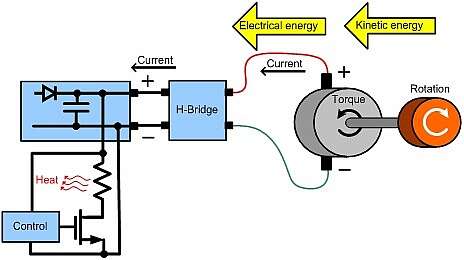

In large systems, it is usually impractical to use simple clamping, because the energy required to dissipate is too large. In these cases, an active clamping circuit can be used to dissipate energy into a resistive load.

Figure 6 Active circuit clamping for dissipating energy

The clamping circuit works by using a comparator or similar circuit to monitor the supply voltage (Figure 6). If the voltage exceeds the preset threshold (just above the normal operating voltage), the load resistor will switch at both ends of the power supply to dissipate energy.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |