Hardware analysis of brushless and non-inductive DC motor drive

Time:2023-02-19

Views:1306

One of the key points of motor drive is to accurately know the position of the rotor. Inductive motors can only obtain the position of the rotor through sensors, non-inductive motors can only obtain the position of the rotor indirectly. Common methods include back electromotive force method, inductance method, magnetic linkage method, high-frequency pulse method and other intelligent methods. The most widely used method is back electromotive force method

The drive circuit of the back electromotive force brushless induction motor can be divided into three parts: power drive part, control part and rotor position detection part

1、 Power drive part

There are two ways to realize the power drive part, one is to use integrated motor drive IC, and the other is to use discrete components. It is easier to use integrated ICs, and most of the driver ICs integrate multiple protection functions, which is more reliable, but the cost is higher.

There are two types of building with discrete components:

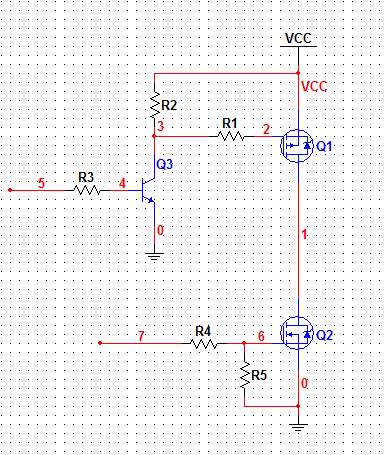

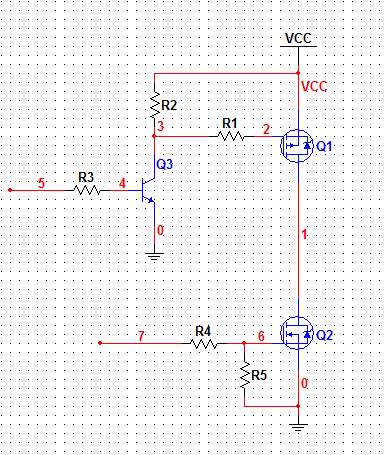

① Use N+P tube, as shown in the figure below. This method is simple to realize, and the duty cycle of PWM control signal can reach 100%. However, the price of P tube is relatively high. Generally, the current is 100A, and the withstand voltage is within 100V. It is mostly used for low voltage and low power applications

R1 and R4 are generally within 100 Ω, but they should not be too small, generally tens of Ω, R2, R3 and R5 are generally several to tens of K

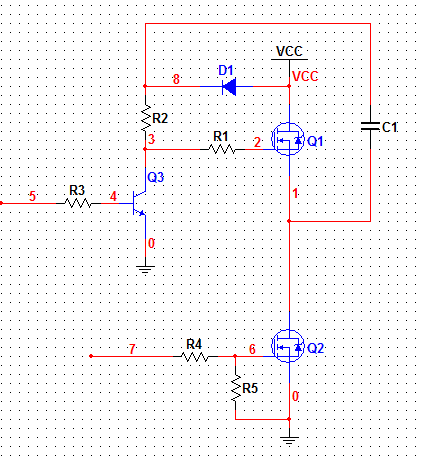

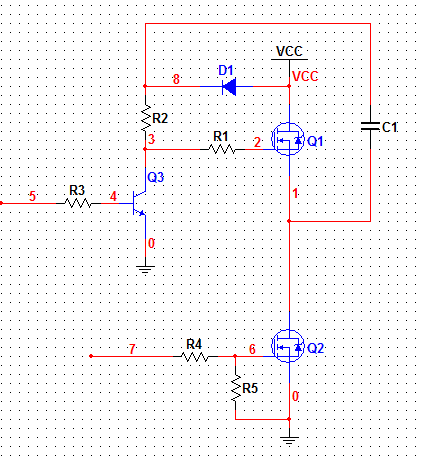

② Use full N-tube, as shown in the figure below, N-tube voltage withstand and power can be selected in a wide range, so it is applicable to various application circuits. However, the upper arm bridge drive is complex. If the bootstrap boost circuit is used, the PWM duty cycle cannot reach 100%

In the figure above, the bootstrap boost of the upper arm is realized in a relatively simple way. D1 is the bootstrap diode, generally the fast recovery diode, and C1 is the bootstrap capacitor. Refer to the formula for the specific size

2、 Control part

This part is roughly the smallest system of MCU, which varies according to the different MCU used. Generally, internal crystal oscillator is used. MCU with comparator and PWM timer is a better choice.

3、 Rotor position detection part

This part is a key part, which varies according to the driving methods used. The main two types are back electromotive force detection and current detection

① Back electromotive force detection

The theoretical basis of this method is that the motor will generate back electromotive force when it is running. At the zero-crossing moment of the PWM conduction device, the end voltage of the suspension phase is equal to the midpoint voltage. The hardware method can establish a virtual neutral point and end voltage comparison. In practice, most of the software sampling comparison method is used

There are three ways to use software for sampling:

1. Sampling at power-on time

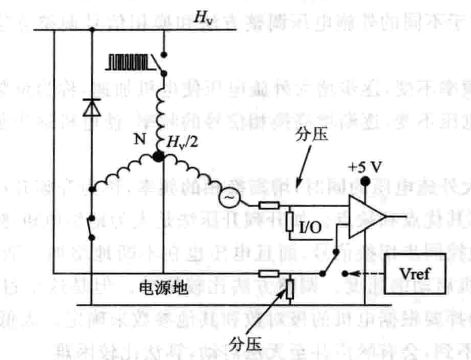

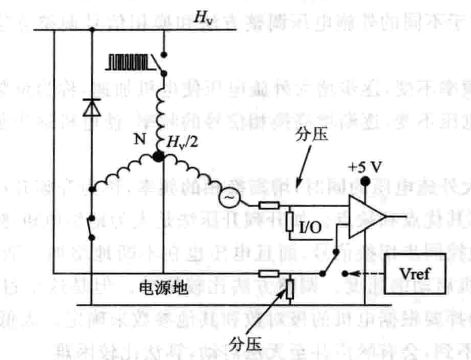

When the two phases are connected, the midpoint voltage is equal to half of the bus voltage, so half of the bus voltage can be used as the reference voltage for comparison with the third phase.

The bus voltage is generally high, and the voltage after half split may be higher than the voltage borne by the MCU port. Therefore, the resistance is generally used to divide the voltage, which affects the detection sensitivity of the zero-crossing point. Moreover, because the sampling is conducted within the turn-on time, there must be a minimum turn-on time, and the low-speed operation of the motor is limited

2. Sampling at the time of power tube closing

When the upper tube is turned off and the lower tube is constant on, the continuous current will flow through the lower tube diode, and the theoretical value of the midpoint voltage is 0. To improve the accuracy, the internal reference voltage of the MCU can be set to a value slightly higher than 0, such as 0.2, and then the third phase is collected and compared with this value.

This method does not require resistance voltage divider, improves detection sensitivity, and suppresses high-frequency switching interference. However, the bearing capacity of MCU port needs to be considered, and a minimum turn-off time needs to be maintained, so the PWM duty cycle cannot reach 100%

3. Sampling in full state of power tube

As shown in the figure below, this method combines the advantages of the above two methods and overcomes the disadvantages of both parties

In most practical application circuits, the first mode is adopted, as shown in the figure below. Both ends are connected to the motor three-wire and MCU respectively

② Current detection method

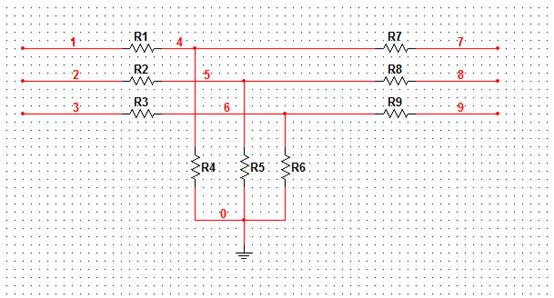

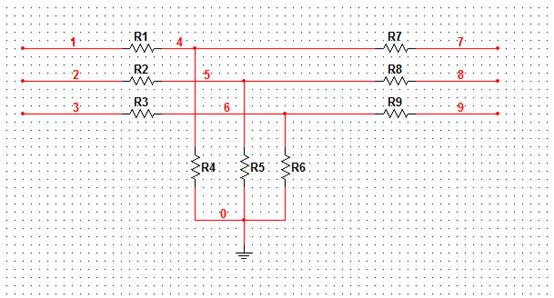

This method is mostly used in FOC control, as follows: connect the current sampling resistor in the three-terminal circuit, collect the phase current, and send it to MCU after amplification by the amplifier,

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |