Why are diodes not suitable for series and parallel connection

Time:2022-06-26

Views:2070

As we all know, resistors can be used in series or in parallel.

So, are diodes suitable for series and parallel connection?

Diode in series

When diodes are connected in series, it is necessary to pay attention to the symmetrical distribution of static cut-off voltage and dynamic cut-off voltage.

In static state, due to the different manufacturing deviation of the cut-off leakage current of the components in series, the components with the minimum leakage current bear the maximum voltage, and even reach the hold state. However, as long as the components have sufficient holding stability, it is not necessary to use voltage equalizing resistors in the circuit. Generally speaking, it is necessary to add a parallel resistor only when the components with cut-off voltage greater than 1200V are connected in series.

Assuming that the cut-off leakage current does not change with the voltage and the error of the resistance is ignored, for the series circuit of N diodes with a given cut-off voltage VR, we can obtain a simplified formula for calculating the resistance:

In formula (1.15), VM is the maximum value of voltage in series circuit, and △ IR is the maximum deviation of diode leakage current, provided that the operating temperature is the maximum value.

We can make a safe assumption:

In equation (1.16), IRM is given by the manufacturer.

Using the above estimates, the current in the resistor is about six times the diode leakage current.

Experience has shown that the resistance value is sufficient when the current flowing through the resistance is about three times the diode leakage current at the maximum cut-off voltage. But even under this condition, considerable losses will still occur in the resistance.

In principle, the dynamic voltage distribution is different from the static voltage distribution. If the carrier of one diode PN junction is smaller than that of the other, it will bear the voltage earlier.

If the capacitance deviation is ignored, we can adopt a simplified method to calculate the shunt capacitance when n diodes with a given cut-off voltage value VR are connected in series:

In equation (1.17), △ qrr is the maximum deviation of the stored electric quantity of the diode.

We can make a fully safe assumption:

The condition is that all diodes are from the same manufacturing batch number. △ qrr is given by semiconductor manufacturer. In addition to the stored power when the freewheeling diode is turned off, the power stored in the capacitor also needs to be replaced by the opening IGBT. According to the above design formula, we found that the total stored power value may reach twice the stored power of a single diode.

Generally speaking, the series current of freewheeling diode is rare, because there are loss sources of the following accessories:

N-fold diffusion voltage of PN junction;

Loss in parallel resistance;

Additional storage power required to be replaced by IGBT;

Increase of components caused by RC circuit.

Therefore, when the diode with high cut-off voltage can be adopted, the series scheme is generally not adopted.

The only exception is that when the application circuit requires very short switching time and very low storage power, these two points are exactly what the low voltage diode has. Of course, the on state loss of the system will also increase greatly.

Pole tube parallel connection

Diodes are connected in parallel and no additional RC buffer circuit is required. It is important that the deviation of on state voltage should be as small as possible in parallel connection.

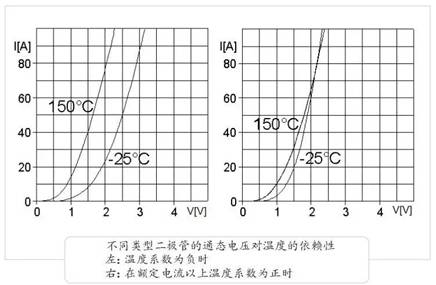

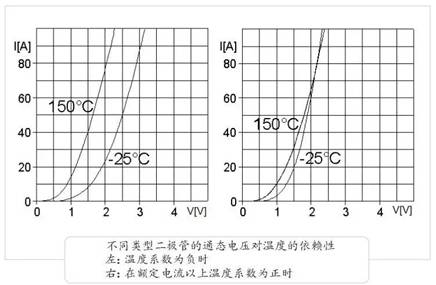

The important parameter to judge whether a diode is suitable for parallel connection is the temperature dependence of its on state voltage. If the on state voltage decreases with the increase of temperature, it has a negative temperature coefficient. This is an advantage for loss.

If the on state voltage increases with the increase of temperature, the temperature coefficient is positive.

In typical parallel applications, this is an advantage because the hotter diode will withstand a lower current, resulting in system stability. Because there is always a certain manufacturing deviation in diodes, when diodes are connected in parallel, a large negative temperature coefficient (> 2mv/k) may cause the risk of temperature rise imbalance.

Parallel diodes produce thermal coupling:

Passing a substrate in a module with a plurality of chips in parallel;

When a plurality of modules are connected in parallel to a heat sink, they pass through the heat sink.

Generally, for the weak negative temperature coefficient, this kind of thermal coupling is enough to avoid the temperature imbalance of the diode with the lowest on state voltage. However, for diodes with negative temperature coefficient > 2mm/k, it is recommended to reduce the rating, that is, the total rated current should be less than the sum of the rated current of each diode.

So, are diodes suitable for series and parallel connection?

Diode in series

When diodes are connected in series, it is necessary to pay attention to the symmetrical distribution of static cut-off voltage and dynamic cut-off voltage.

In static state, due to the different manufacturing deviation of the cut-off leakage current of the components in series, the components with the minimum leakage current bear the maximum voltage, and even reach the hold state. However, as long as the components have sufficient holding stability, it is not necessary to use voltage equalizing resistors in the circuit. Generally speaking, it is necessary to add a parallel resistor only when the components with cut-off voltage greater than 1200V are connected in series.

Assuming that the cut-off leakage current does not change with the voltage and the error of the resistance is ignored, for the series circuit of N diodes with a given cut-off voltage VR, we can obtain a simplified formula for calculating the resistance:

In formula (1.15), VM is the maximum value of voltage in series circuit, and △ IR is the maximum deviation of diode leakage current, provided that the operating temperature is the maximum value.

We can make a safe assumption:

In equation (1.16), IRM is given by the manufacturer.

Using the above estimates, the current in the resistor is about six times the diode leakage current.

Experience has shown that the resistance value is sufficient when the current flowing through the resistance is about three times the diode leakage current at the maximum cut-off voltage. But even under this condition, considerable losses will still occur in the resistance.

In principle, the dynamic voltage distribution is different from the static voltage distribution. If the carrier of one diode PN junction is smaller than that of the other, it will bear the voltage earlier.

If the capacitance deviation is ignored, we can adopt a simplified method to calculate the shunt capacitance when n diodes with a given cut-off voltage value VR are connected in series:

In equation (1.17), △ qrr is the maximum deviation of the stored electric quantity of the diode.

We can make a fully safe assumption:

The condition is that all diodes are from the same manufacturing batch number. △ qrr is given by semiconductor manufacturer. In addition to the stored power when the freewheeling diode is turned off, the power stored in the capacitor also needs to be replaced by the opening IGBT. According to the above design formula, we found that the total stored power value may reach twice the stored power of a single diode.

Generally speaking, the series current of freewheeling diode is rare, because there are loss sources of the following accessories:

N-fold diffusion voltage of PN junction;

Loss in parallel resistance;

Additional storage power required to be replaced by IGBT;

Increase of components caused by RC circuit.

Therefore, when the diode with high cut-off voltage can be adopted, the series scheme is generally not adopted.

The only exception is that when the application circuit requires very short switching time and very low storage power, these two points are exactly what the low voltage diode has. Of course, the on state loss of the system will also increase greatly.

Pole tube parallel connection

Diodes are connected in parallel and no additional RC buffer circuit is required. It is important that the deviation of on state voltage should be as small as possible in parallel connection.

The important parameter to judge whether a diode is suitable for parallel connection is the temperature dependence of its on state voltage. If the on state voltage decreases with the increase of temperature, it has a negative temperature coefficient. This is an advantage for loss.

If the on state voltage increases with the increase of temperature, the temperature coefficient is positive.

In typical parallel applications, this is an advantage because the hotter diode will withstand a lower current, resulting in system stability. Because there is always a certain manufacturing deviation in diodes, when diodes are connected in parallel, a large negative temperature coefficient (> 2mv/k) may cause the risk of temperature rise imbalance.

Parallel diodes produce thermal coupling:

Passing a substrate in a module with a plurality of chips in parallel;

When a plurality of modules are connected in parallel to a heat sink, they pass through the heat sink.

Generally, for the weak negative temperature coefficient, this kind of thermal coupling is enough to avoid the temperature imbalance of the diode with the lowest on state voltage. However, for diodes with negative temperature coefficient > 2mm/k, it is recommended to reduce the rating, that is, the total rated current should be less than the sum of the rated current of each diode.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is infringement or objection, please contact us to delete. thank you! |